Removing Tires Without Tools

Here’s why we love really good tubeless-ready rims: The rim/tire fit is about perfect. It has to be – otherwise the tire can blow off, since there’s no tube to reinforce the transition from tire to rim. This means it’s easy to mount tires, and also easy to take them off. In fact, for the best rims, you don’t even need tools.

And yet many cyclists experience frustrations when working with tubeless-ready rims. You can’t treat them like classic rims, where the tire bead automatically went slack as you deflated the tire. With tubeless-ready rims, you need to push the bead into the rim well all the way around the tire. Then the tire comes off without struggle.

In the ‘Project’ articles in the current Bicycle Quarterly (No. 79), you find illustrated step-by-step instructions on how to mount tires – and take them off – without hassle and usually without tools. There are many small tricks that make the process easy and frustration-free.

As an aside, some may suspect that the tire shown in the video has a loose fit on the rim, but that’s not the case. After removing the tire, we installed it tubeless and inflated it to 95 psi (6.5 bar) – slightly above the maximum pressure of the rim – then left it for 24 hours without any problems. (Warning: Do not exceed 60 psi/4.1 bar when running Rene Herse tires tubeless. And always use rims that meet the applicable ETRTO standards.)

The second part of the article talks about patching tubes. Why tubes? Tubes and tubeless installations both have their place. Tubes have the advantage of being easy to install, maintenance-free and ultra-reliable. They work well in cold weather where latex-based sealants no longer seal punctures. Tubeless is great in terrain so rough that pinch flats are a concern, and also if you ride on shoulders of busy highways that are littered with small steel wires left behind by shredded truck tires. Sealant will (hopefully) take care of those punctures.

For those of us who ride on empty back roads where flats are rare, tubes remain a great option – except when they flat. Patching punctured tubes is not just a great money saver – even if you count your time – but also keeps those tubes out of the landfill. Glueless patches are temporary fixes – for a permanent repair, you need vulcanizing fluid to fuse the patch permanently with the tube.

When I was a college student riding on worn-out tires in a city full of broken glass, I had many flats, and I wasn’t very good at patching them. An Italian bike racer roommate took pity on me and showed me how to get patches to stick 100% of the time. In this how-to article, we share those secrets and more.

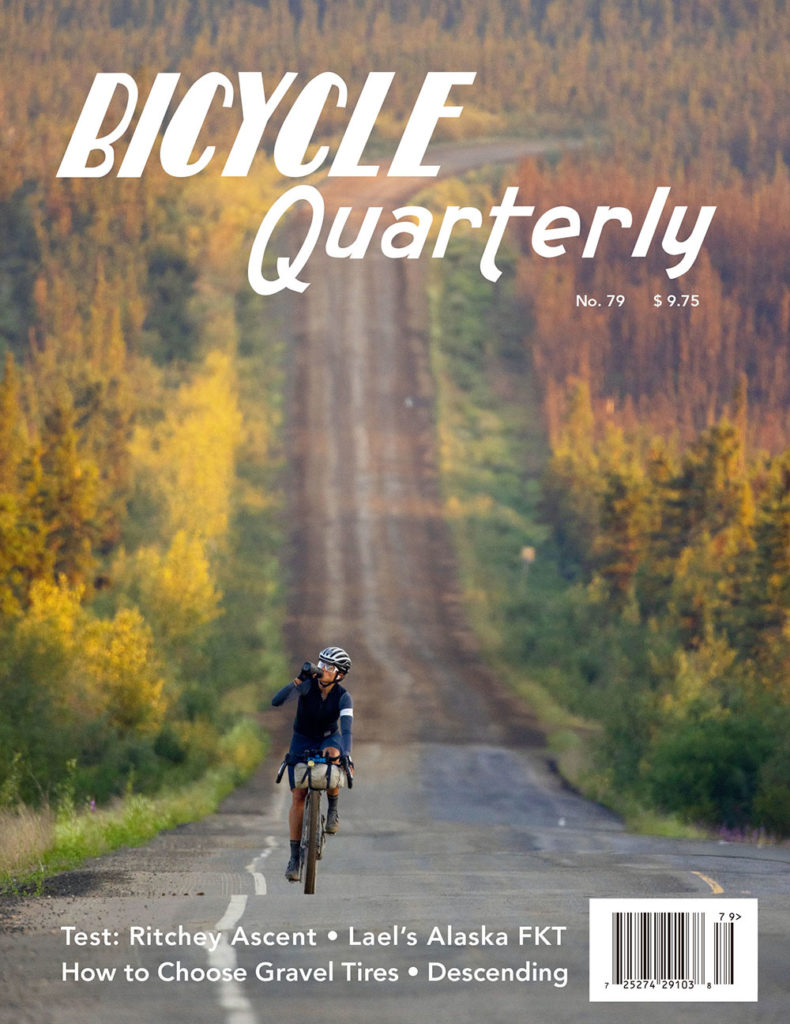

These two ‘Project’ articles comprise just ten of the 108 pages of the Spring 2022 Bicycle Quarterly. Lael takes you on her FKT ride on the Alaska Pipeline Trail – where she rode faster than the oil flowed in the pipes. We test an affordable adventure bike, the Ritchey Ascent. You’ll read the story of Romolo Stanco, whose unorthodox bikes – with steel frames and wide tires – keep winning races and even national championships in Italy. And speaking of tires, we look at how to select the perfect gravel tires for your riding style and terrain – and discover that sometimes, running narrower tires makes sense even though they roll a little slower.

Click here for more information about the Spring 2022 Bicycle Quarterly.