Why Bolts Come Loose

Fenders, racks and other attachments can remain maintenance-free for 10,000+ miles, yet other bikes require tightening bolts on a regular basis. Why do some bolts stay tight, while others loosen quickly?

We have covered this in detail in Bicycle Quarterly’s article “Engineering a Bicycle” in Vol. 5, No. 4. The essential concept is simple: Vibrations of parts allow bolts and nuts to loosen. (At the end of the post is a link to a video that shows this in action.) The more parts you have that vibrate, the quicker your bolts loosen. Here is how to avoid this:

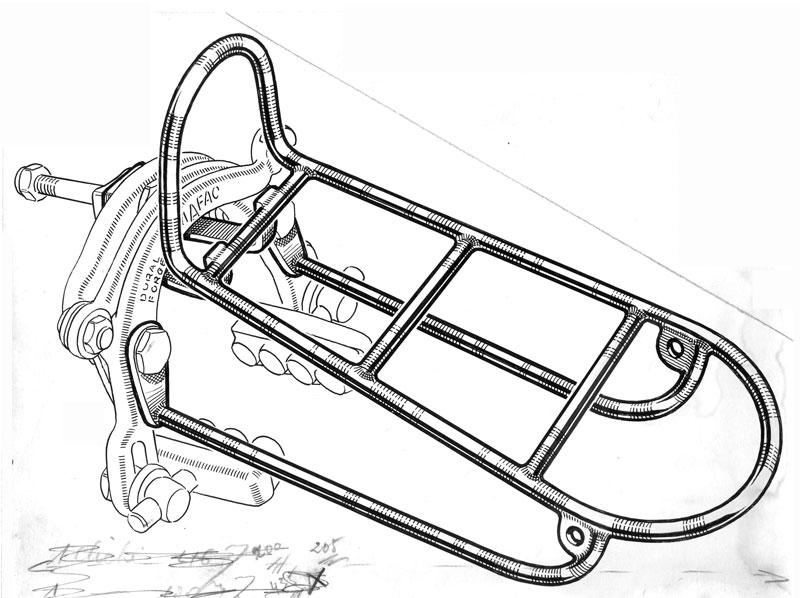

Do not use the same bolt to attach several things. The more “layers” you have, the more movement results, and the quicker the bolt will loosen. This is especially true for front racks that are attached to the posts of cantilever (or centerpull) brakes.

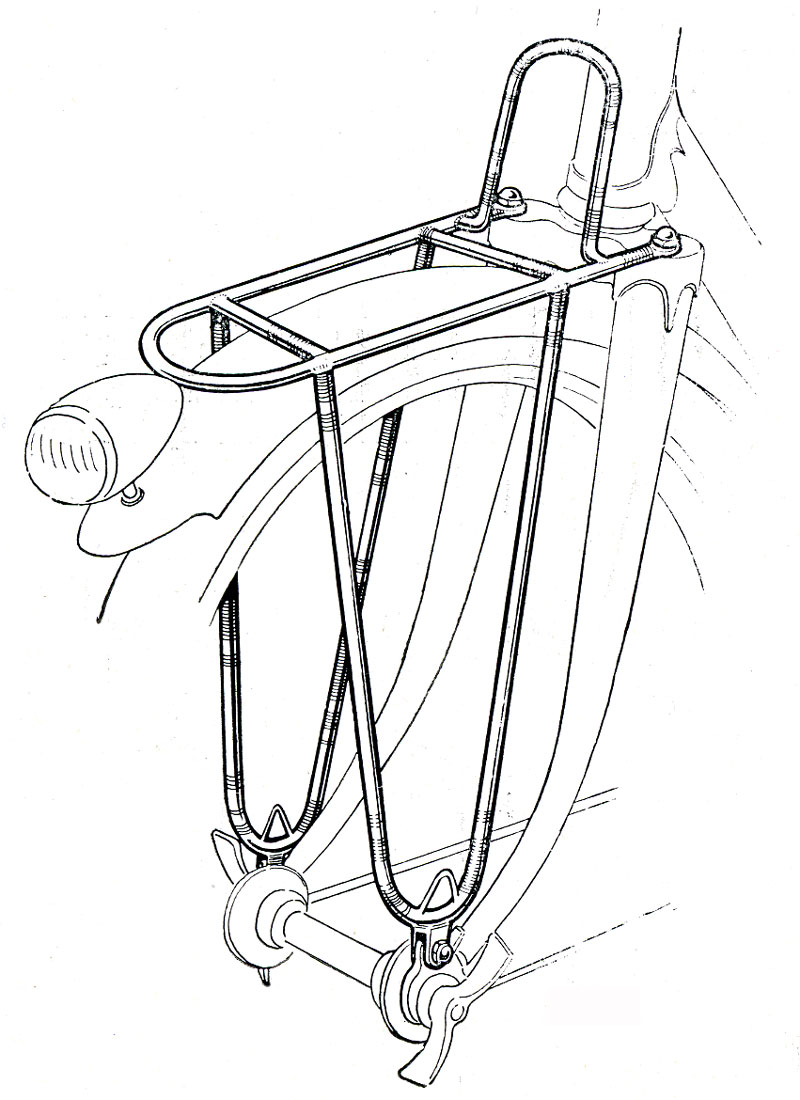

The rack above is more likely to come loose than the one below, which uses a bolt with a forward extension, onto which the rack is mounted.

Even simple metal washers increase the risk of bolts coming loose by adding another layer between bolt and the surface into which the bolt threads. Spacers are even worse, because they provide a longer lever arm for the forces that vibrate the bolt head.

Washers should be used only where they are needed, for example, to provide a smooth surface when a bolt head tightens onto paint or aluminum. Spacers should be avoided in most situations. (It is better to make your parts to fit together properly.)

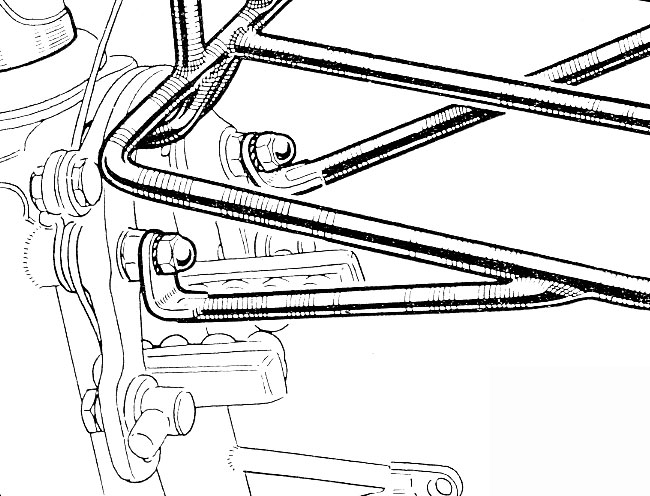

All connections should be designed so that the bolts won’t tend to rotate. For example, the rack below attaches to the fork crown with straight tubes that are aligned to the vibrations of the rack (forward and backward).

If these connecting tubes were angled or even curved, then each vibration would tend to turn the bolt.

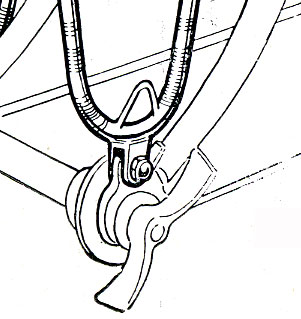

Another neat detail of this particular rack is the forked mount for the lower bolts that carry the weight of the load. This is the best possible attachment. Here is why:

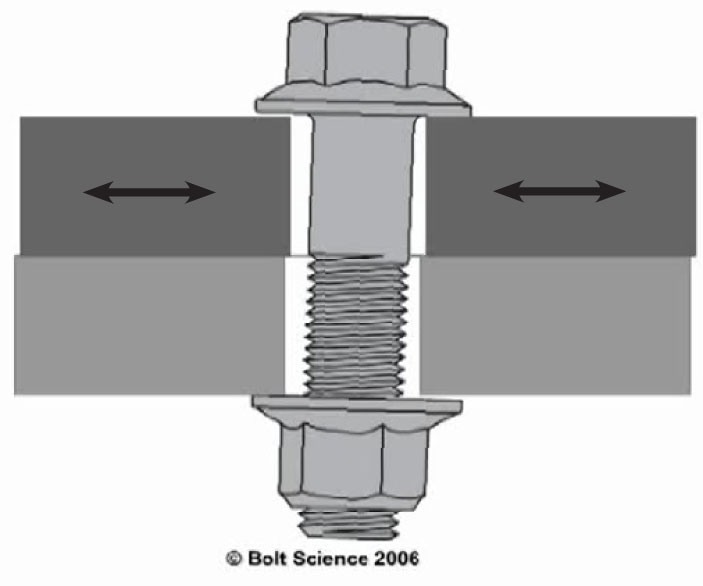

With a simple mount (above), the surface underneath the bolt head and the surface underneath the nut move independently from each other. The bolts loosens as the parts vibrate.

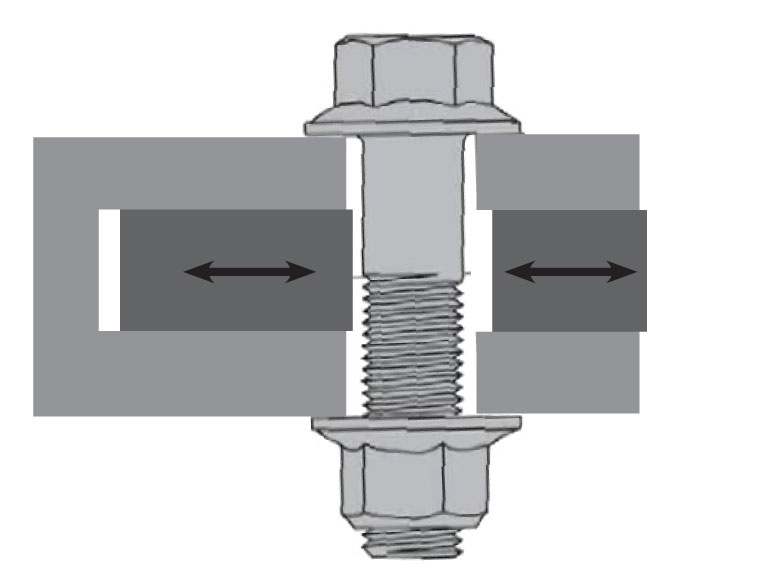

With a forked mount (above), the two surfaces (under the bolt’s head and under the nut) no longer move against each other, so the bolt experiences much less force that could loosen it.

There is more to consider when designing good connections. And it’s true that even sub-optimal connections can work fine. The bottom line is simple: On a well-designed bike, there should be little need to re-tighten bolts.

Recently, Peter Meilstrup posted a link to video that shows how bolts loosen. I find it especially impressive to see how the nuts turn as they vibrate. And commonly used lockwashers actually make things worse! It is obvious that there is no substitute for good design. Click here to see the video.