Why No Half Knobs?

We get that question sometimes: “Why don’t you offer tires with smaller or shallower knobs?” At first glance, it seems like Rene Herse offers only extreme tires. Our tires are either almost slick or have large knobs. Wouldn’t an ‘in-between’ tire offer the best of both worlds – just a little more grip than a smooth tire, without giving up much speed?

We already know that our knobbies excel when the going gets rough. The large knobs dig deep into mud, snow and loose surfaces. The wide spaces between the knobs help clean the tread as the tire rotates, so the knobs remain effective even in sticky mud (or snow).

Yet most of the time, we don’t ride in such extreme conditions. We want just a little extra grip on loose surfaces, while giving up as little speed as possible. In fact, there are plenty of semi-slick tires on the market, because they seem to make sense. Wouldn’t it be great to combine such an ‘in-between’ tread pattern with our ultra-supple casings? There is only one way to find out: Try it!

But how? Making a new tire mold is expensive, and we don’t want to add a new model to our program unless it offers real benefits. It’s a chicken-and-egg question: You can’t test tires without making the tooling, but you can’t justify the expense for the tooling unless you are going to use it to produce tires. And if you’re going to make the tires anyhow, there is little point in testing their performance. That’s why most companies just make tires without much testing, and let the marketing department explain why they are ‘better.’

That’s not how we do things. All Rene Herse products are born out of a real need. We don’t make tires or components unless they offer better performance. (As an aside, ‘performance’ doesn’t just mean speed, but also comfort and reliability.)

We’re fortunate to have friends who are just as committed to the goal of making bikes faster and more fun. J. P. (Peter) Weigle is best known for his beautiful custom randonneur bikes, but he’s also an excellent rider. Few people know that he won the national cyclocross championships in his younger years. Peter has been a great inspiration and collaborator.

At his workshop deep in the woods of New England, Peter figured out a way to shave the knobs off tires. Shaving tires requires a lot of skill, and it’s also quite messy, so we are immensely grateful that he has done this for us. Peter made us a few sets of custom tires with knobs that are half as tall as our Hurricane Ridge 700x42s. You can see one of those shaved tires in the first photo (left tire).

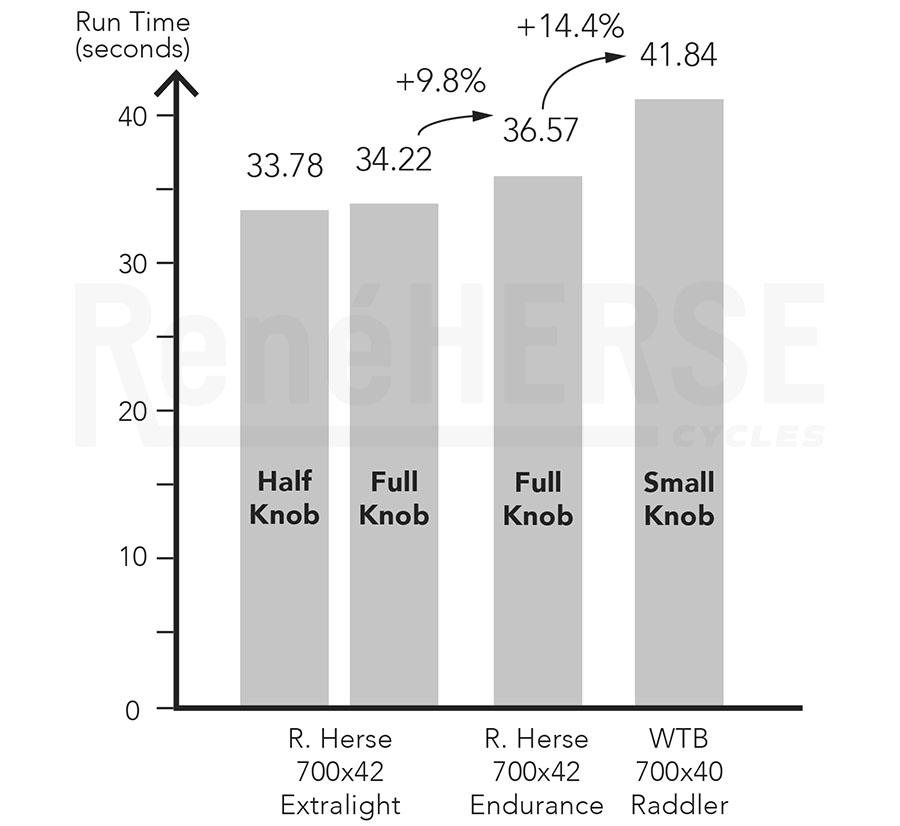

Shaved tires in hand, we waited for perfect conditions (zero wind, constant temperature) and tested the tires in a real-road roll-down test – with a rider on the bike, so that we measure not just tire deformation, but also suspension losses and all other factors that affect the bike’s speed. We ran the shaved tires against a set of full-height knobbies – both with the same Extralight casings. For comparison, we also tested the same Hurricane Ridge knobbies with the tougher Endurance casing. We also included a set of WTB Raddlers, a knobby with small center knobs and larger shoulder knobs, in their ‘Light, Fast-Rolling’ casing.

As always in our testing, we ran each tire multiple times, and we did a careful statistical analysis to make sure the results we are seeing are meaningful. It’s important to do the testing right!

The results show that the shaved knobs roll at almost the same speed as the full-height knobs. The small difference we measured isn’t statistically significant. That means we don’t know whether it’s real or just ‘noise’ in the data. In any case, it’s too small to warrant adding another tire model to our program.

The real difference comes from different casings: The Endurance tire rolled almost 10% slower than the Extralights, whether with full-height of half-sized knobs. And the WTB Raddler was 24% slower. It’s important to know that these are low-speed tests. They over-emphasize rolling resistance, so that we can pick up very small differences. (At higher speeds, wind resistance becomes the dominant factor.) At real-world speeds, the difference between the fastest and slowest tires shown above is about 5% – still much more than a set of aero wheels. (See the links at the bottom for more information about our tire tests.)

There’s a simple reason why shallower knobs don’t make our tires faster: We’ve optimized the knob size and spacing so that the knobs don’t deform and squirm as the tire rolls. Making the knobs shallower doesn’t provide any real benefit, because even the full-height knobbies roll as fast as our smooth all-road tires.

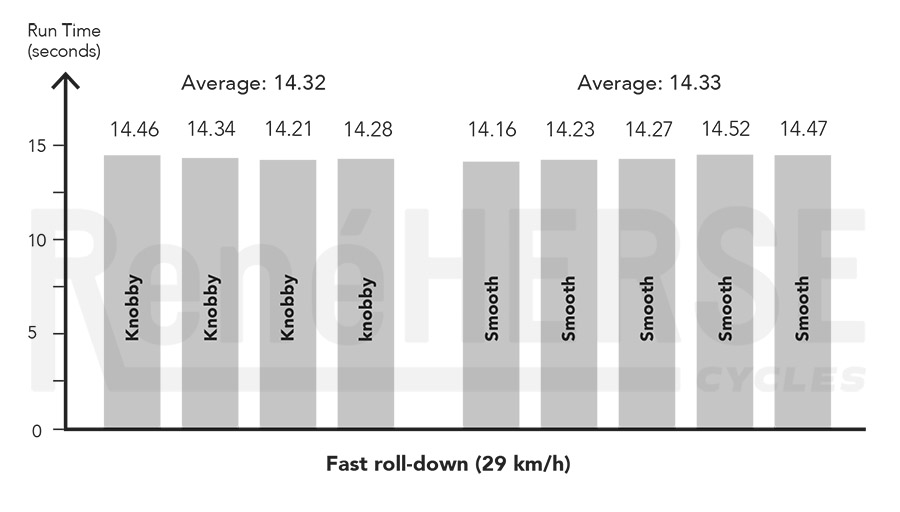

Above is a roll-down test at higher speeds (29 km/h or 18.0 mph). On the left are four runs with the 700×42 Hurricane Ridge knobbies. On the right are five runs with the smooth 700×44 Snoqualmie Pass. The speeds are identical. In real-world terms, this means that if you ride our knobbies and your friend rides our smooth tires, you won’t have to pedal harder (or get dropped) because of your tire choice.

The optimized knob shapes and spacing also make our knobbies corner like slicks. The knobs don’t squirm or fold over, and they always put the same amount of rubber on the road. So you have none of the sudden break-away that you get with other knobby tires when the knobs suddenly fold over. The result is a knobby that doesn’t just roll as fast as a slick, but also corners like one – even on pavement.

When we developed our dual-purpose knobbies, our goal was to create tires that excel in muddy and loose conditions without giving up anything on paved roads. Back then, conventional wisdom held that this was impossible, that you had to make compromises when you rode knobbies – but nobody had really tried to eliminate those compromises. By carefully analyzing the forces on each knob, we were able to make the knobs large enough so they don’t squirm, but small enough so they dig into the surface. It took a lot of R&D, but it means there’s no need for dozens of tread patterns that don’t offer any real performance differences. We’d rather invest the money into tire molds in more sizes – that’s how we can offer tires from 26 to 55 mm wide, in three wheel sizes.

This also makes your tire choice easy. There’s no need to overthink it: Run our smooth all-road tires when it’s dry and firm. Run our dual-purpose knobbies when it’s muddy or loose, or when you just don’t know what lies ahead. Either way, you’ll know that you aren’t giving up any performance: Rene Herse tires are among the fastest in the world, no matter which tread pattern you choose.

Further reading:

- Test results of Rene Herse and other tires.

- The Spring 2021 Bicycle Quarterly has the full test of our knobbies: How do knob height, wear, tire pressure and other factors affect speed.

- Our book ‘The All-Road Bike Revolution’ discusses the research that has revolutionized our understanding of how bikes work: tire performance, frame stiffness, frame geometry and every other aspect that determines the performance, comfort and reliability of your bike.