The Next Revolution: Smaller Wheels

April 1, 2021: Rene Herse is announcing a new wheel size for performance bikes: 13-inch wheels. With a bead seat diameter of 230 mm, the smaller wheels will improve performance by allowing the tires to operate closer to their optimum temperature range. “It’s our latest innovation, and another way of thinking outside the box to improve performance and fun for every cyclist ,” explained Jan Heine, president of R&D at Rene Herse Cycles.

In the past, it was sometimes believed that larger wheels roll faster, but this has been disproven by numerous tests: There is no difference in speed and resistance for wheels of different sizes – provided the tires use the same supple casings. New research shows that smaller tires actually roll faster, because they heat up more as they roll, so their rubber is closer to the optimum temperature.

It’s been known for a long time that rubber gets softer as it heats up, and that softer tires have less rolling resistance and better cornering grip. As cyclists, we have noticed that we go slower when it’s cold. It’s not because our bodies don’t work well in the cold – after all, we dress appropriately – but because our tires use more energy as they deform. Riders who are finely attuned to their bikes also notice that they are less comfortable when it’s cold, because cold tires transmit more vibrations.

The optimum operating temperature for rubber tires is between 85 and 95°C (185 – 203° F). Even in the desert of Arizona, a bike’s tires are running at sub-optimal temperatures. Wouldn’t it be nice if we could heat our tires somehow?

Car racers use tire heaters to warm up their tires before a race. This works because, once on the circuit, the forces of cornering, accelerating and braking keep a racing car’s tires hot. Bicycle tires will quickly cool, simply because cyclists don’t have enough horsepower to generate these forces. Thus we must find another way to keep putting heat into our tires.

First we thought about heating the tires electrically. Small filaments could incorporated into the tire casing. They’d be powered from a generator hubs and continuously heat the rubber. However, the filaments would make the tire less supple, and the power draw to generate the electricity would add resistance. Our calculations show that the associated losses would be greater than any gains from the softer, more supple rubber.

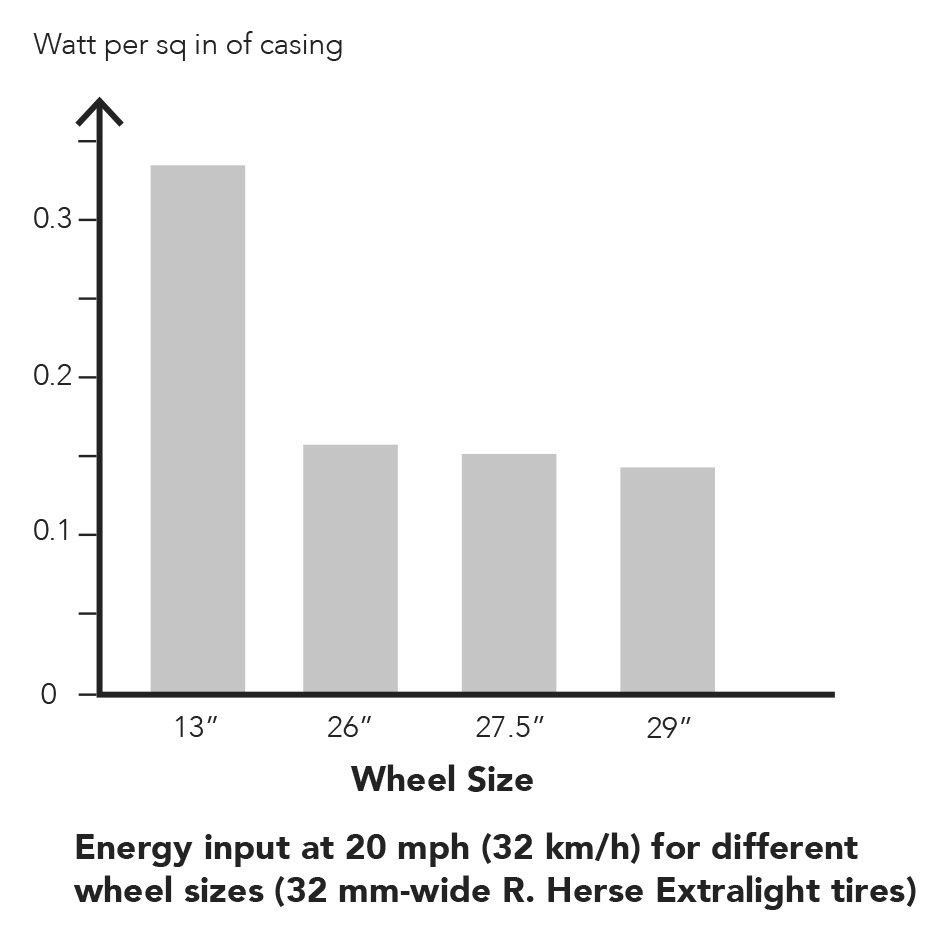

Fortunately, there is a much simpler way to heat the tires without additional energy losses: Use the hysteretic losses that occur when the tires flex as they rotate. These losses convert energy into heat – but with standard-sized wheels, there just isn’t enough to heat the tire significantly. The energy is spread over too much material. By making the wheel smaller, the heating is concentrated on a smaller rubber surface, hence the tire gets warmer with the same amount of friction. And since the smaller wheel has a smaller frontal area, it is also cooled less by the airstream.

It’s simple physics: A 13″ wheel is half as big as a 26″ wheel, so it spins twice as fast. This means there will be twice as much heating from friction and hysteresis.

During the R&D for the new concept, Rene Herse has tested a variety of wheel sizes on specially constructed prototype bicycles. Testing under real-world conditions has provided valuable insights. Some wheels were too small to roll smoothly over rough roads…

… while others were too big to provide optimum heating of the tires. It turns out that 13″ wheels are the best compromise. This also still allows for the correct gearing without having to use chainrings that are larger than the crankarms. Perhaps not coincidentally, 13″ wheels have been used on Formula 1 race cars for more than 25 years…

Beyond the heating of the rubber compound, additional advantages of the smaller wheels are:

• better braking with disc brakes – a given rotor size is larger in proportion to the wheel size, so it has more leverage.

• lighter weight from smaller rims and tires, and shorter spokes.

• closer drafting made possible by the smaller wheels. For riders who want to draft closely, but not offer the same advantage to others, a standard-diameter rear wheel can be used. (But they give up half the advantage.)

“It makes perfect sense,” commented Gérard Vroomen, co-founder of Cervelo and OPEN. “I’m amazed that nobody else has thought of this.” OPEN is the first company to introduce a ‘Thirteener.’ The OPEN MI.NI. will be introduced this autumn. It’ll be designed around Rene Herse’s new tires. 13″ carbon rims are in development by a number of makers, and larger chainrings will be offered by Rene Herse, not just for the company’s own cranks, but also for popular cranks from other makers.

For pro racing, there is still a hangup, though: Current UCI rules specify a minimum outer wheel diameter of 550 mm. Rene Herse has petitioned the sport’s governing body to change this rule. “The advantages are just too great to ignore,” explained Jan Heine. After wide and supple tires, small wheels may be the next thing to revolutionize bicycles.