Return of the Hook: Enve’s Newest Wheels

Enve raised quite a few eyebrows with their new SES 4.5 Pro wheels. Made specifically for Tour de France winner Tadej Pogačar and his UAE Team Emirates, the new wheels are narrower than their predecessors. They also incorporate a bead hook, after years of hookless Enve wheels. What is going on here? Are all the innovations in wheel tech unraveling?

To find out more, I’m lucky to know just who to ask: Jake Pantone is Vice-President of Product and Brand at Enve (below). We go back a long time, ever since Enve and Rene Herse worked together on tubeless and hookless rim safety to establish the current rim standards of the ETRTO (European Tyre and Rim Technical Organization) and the ISO (International Standards Organization). We chatted off the record, but he agreed to share our conversation with just a few edits to protect company secrets. Here’s what’s going on with the new wheels:

JH: Congrats on another Tour win on Enve wheels. Even though it’s almost routine, it must feel good!

Jake Pantone: Thank you. Yes, it feels good to have that done and dusted. Tadej is something else! Although he’s the expected favorite, the duration of the Tour is just so long. It’s stressful to some degree, given that even the strongest rider is just a touch of bars or wheels away from disaster.

JH: Good wheels certainly help when it comes to avoiding disaster! Speaking of which, let’s talk about Tadej’s SES 4.5 Pro wheels. What is the story?

Jake: The main objective of the 4.5 Pro was a lighter-weight wheel for Tadej and UAE. Historically, their bikes have been on the heavy side, which has put a lot of pressure on ENVE to make a lighter wheel. We’ve always shied away from superlight in order to preserve reliability and safety, but we also know how to make a lighter rim, so we did that. Plus, we did a bunch of work on the hubs to take out literally any weight that was redundant and unnecessary for reliable performance.

JH: OK, that makes sense. How does it relate to the fact that the new wheels have hooks? Enve was one of the pioneers of hookless rims. I’ve heard a lot of speculation about why you went back to hooks, but I wanted to ask the source instead of speculating myself.

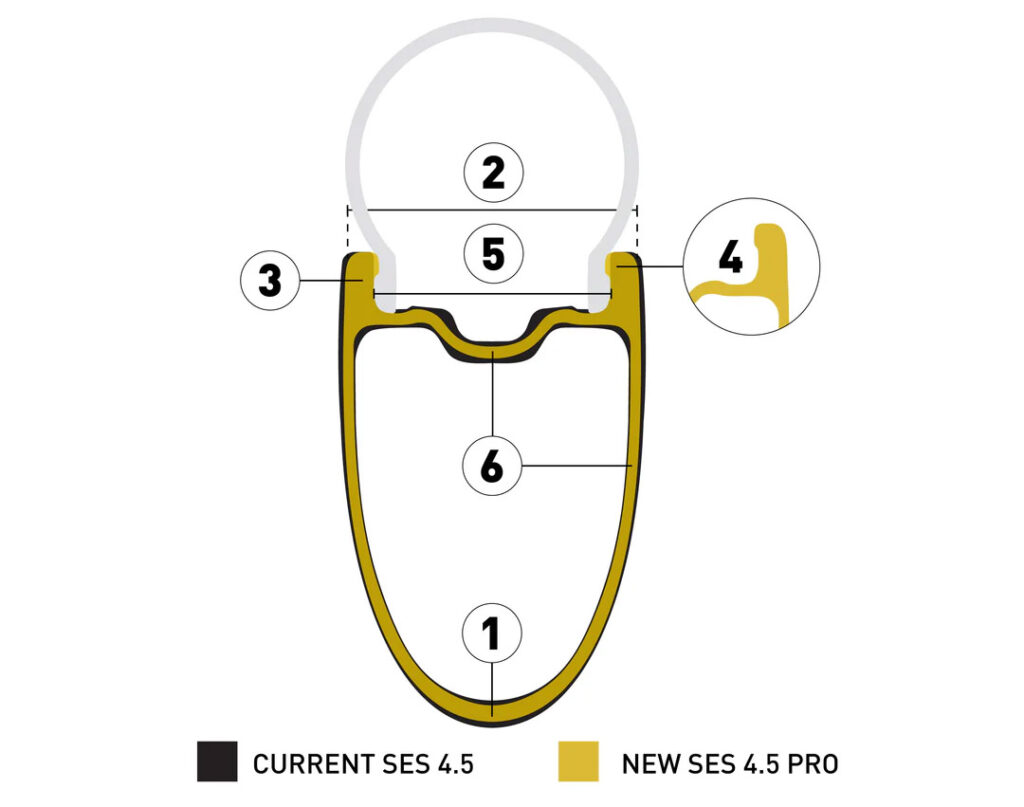

Jake: The micro-hook is primarily a weight savings solution.

JH: That’s interesting! I remember when hookless came about, and it was lighter and stronger than the hooks you had before. What has changed since then?

Jake: You are right, we used to have non-tubeless, hooked rims. However, when tubeless came along, the hooks prevented us from achieving the most accurate/precise dimensions because of the ‘undercut’ in the molds. So we eliminated the hooks, and made precise hookless tubeless rims. As you mentioned, this saved some weight. Then we had issues of pinch-flats because the leading edge, without the hook, was so thin. So we added material, and we introduced what we call the Wide Hookless Bead.

JH: I remember that. I was riding a test bike with the then-new wheels and 42 mm tires. We went on a trail high in the Cascade Mountains that had been a creek bed not long ago. We were riding over huge cobbles, and I was seriously under-tired. My rims bottomed out again and again. But no pinch flats, even though I was running butyl tubes back then. The wide rim sidewalls distributed the loads, and the tubes never suffered. That was amazing!

Jake: Yes, it works really well. However, the wide sidewalls added back weight. So today, the 4.5 PRO maintains that critical wide leading edge, but then we remove the material from below the leading edge. We’re achieving a hook in the process. Kills two birds with one stone, so to speak. We get lighter, and we hedge against the potential of any negative UCI decisions around hookless.

JH: The possibility that the UCI suddenly changes the rules probably keeps you up at night! I can see that you want to prepare for all eventualities… How does the hook work from a manufacturing perspective? If you remove the material after molding the rim, aren’t you weakening the carbon structure? And if you make the hook part of the mold, aren’t you back to the dimensional inaccuracies that led you to hookless in the first place?

Jake: The hooks are all molded in. We have developed a new-to-ENVE process for removing the rigid tooling from between the hooks, so there’s none of the inaccuracy that we got previously when the space between and underneath the hooks was created with inflatable bladders.

JH: Glad to hear that tire fit is as good as it’s been with the hookless rims.

Jake: Yes, the hook is not explicitly a feature to improve tire retention. We’ve done the testing. Hooked or hookless, the key for a tire staying on a rim is all about the dimensions of the tire and rim, tire construction etc…

JH: That makes sense. We found that hooks prevent a loose-fitting tire from lifting off the rim in one spot. Basically, hooks keep the tire concentric on the rim, with the same amount of looseness all around. But it’s much better if the tire isn’t loose in the first place. If the tire sits firmly on the bead seat of the rim, hooks aren’t necessary—in fact, they don’t do anything unless the tire lifts off the bead seat.

Jake: Exactly. We’ve blown tires off some competitors’ hooked rims at pressures lower than what our hookless rims support. At some point, the air pressure will stretch any tire so it starts lifting, and then hooks do increase max blow off pressure. But that doesn’t become relevant until you’re at pressures north of 130-140 psi (9.0-9.6 bar).

JH: Fortunately, that’s not a pressure anybody is running any longer, except perhaps on the track with tubular tires.

Jake: Right. Based on our testing, hooks are irrelevant as a real-world contributor to safety.

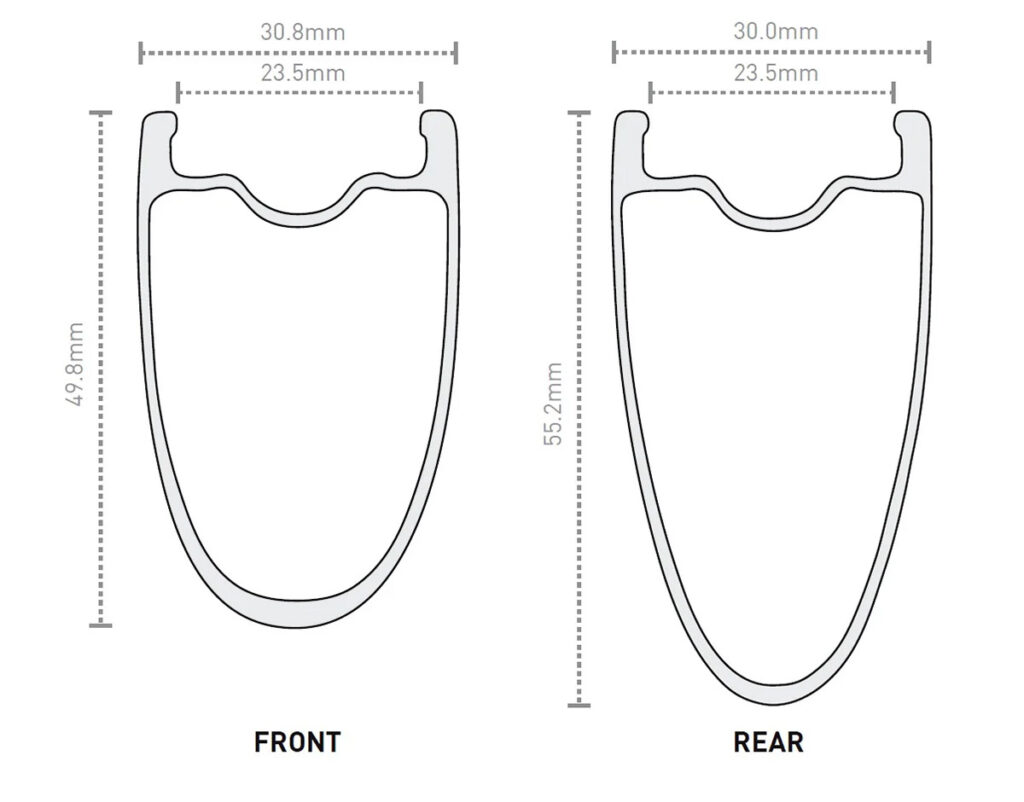

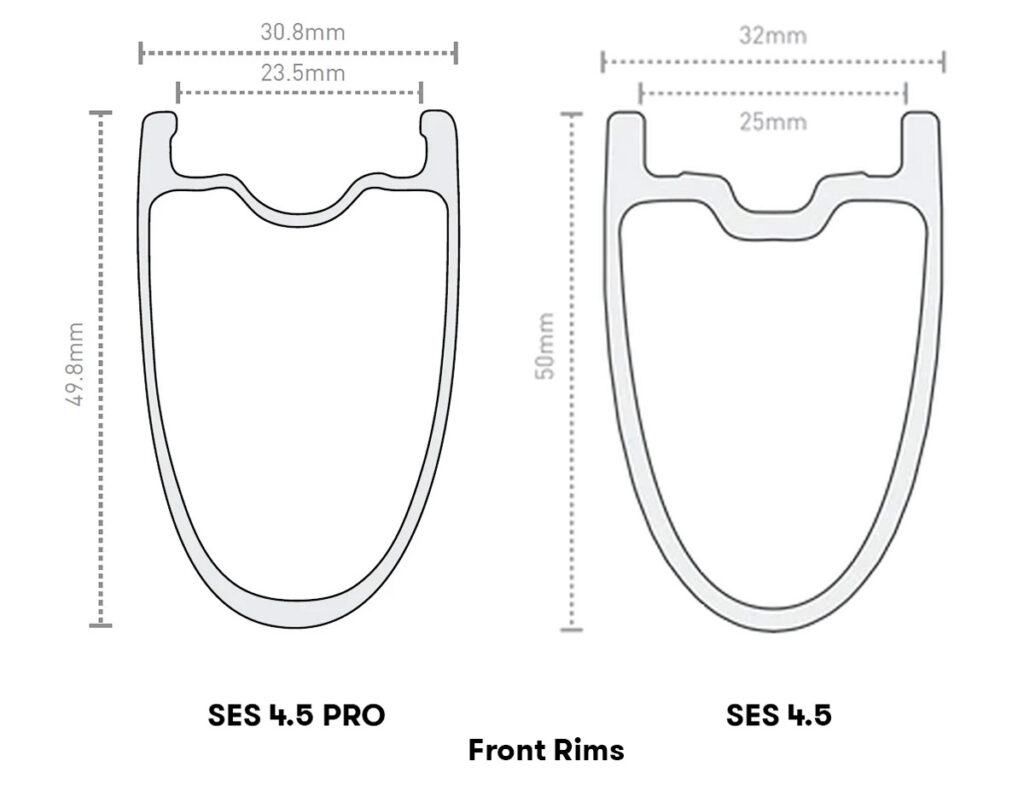

JH: What about the width? The new Pro rims measure 23.5 mm internal (left), whereas the standard SES 4.5 are 25 mm wide (right).

Jake: Team UAE is a Continental-sponsored team, and they like to run the Conti 28 mm tires. The width of 23.5 internal is all about being ETRTO-compliant with a 28 mm tire. And we already have the standard 4.5 and its 25 mm internal width, so riders have that option if they want to aero-optimize wider tires. To be honest, we kind of game this a bit. The 0.5 mm hooks are where the 23.5 mm inner width is measured. However, underneath the hooks, where the tire bead actually rests, is 24.5 mm, so nearly the same inner rim width as our standard 4.5.

JH: There’s been much talk about the new Archetype tire, made specifically for Tadej, with ultra-soft rubber and no puncture protection, for the ultimate in speed. The Archetype comes only in a 30 mm width (nominal) or about 31 mm when mounted on your rims. Doesn’t that violate the ‘Rule of 105’—that the rim should be at least 5% wider than the tire so the airflow doesn’t get disrupted as it transitions from tire to rim?

Jake: You are right, in the wind tunnel, the SES 4.5 PRO is actually slower than the standard SES 4.5 if you run a Conti 30. The 4.5 PRO only contends aerodynamically if you run a smaller tire, like the Conti 28. At the Tour, the UAE squad generally used standard SES 4.5 when they were using the GP 5000 30 mm, or the new Archetype tire. When the stage was hilly or mountains, they went SES 4.5 Pro and GP 5000 TT 28 mm.

JH: Interesting! What about the much-vaunted aero and rolling resistance advantages of hookless rims? Do you lose those with the new rims?

Jake: We still see subtle advantages in aero and rolling resistance with hookless. But there is also the reality that we can design a rim with hooks and make it just as fast, especially when you consider the realities of having to comply with the UCI / ETRTO rules mentioned earlier.

JH: In the drawings, we can really see how you’ve slimmed down the rim to an absolute minimum. How much weight do you save on the rims? And how much on the hubs?

Jake: Making the rim narrower actually saved the most weight. The PRO rims are 50 grams lighter each than the standard SES 4.5—a total of 100 grams. We save an additional 60 grams on the hubs.

JH: With all the focus on light weight, why no carbon spokes? Enve is known for carbon, so you must have a reason…

Jake: We’ve tested carbon spokes, and while they’re lighter, their shape reduces aerodynamic performance. So we’re not giving up on them, we just haven’t found a solution we’re comfortable with yet in terms of performance.

JH: Last question: Will the hooks remain unique to the SES 4.5 Pro, or will we see them on other models, too. Like, are my absolute favs, the SES 3.4 climbing wheels, going to get even lighter in the future?

Jake: At this time, hooks will remain unique to the ‘Pro’ wheels. If, in the future, we decide to do a 3.4 Pro, the rims would include the micro-hook.

JH: Jake, thanks for all the insights. It’s nice to see you’re still pushing the performance envelope, without compromising tire fit and reliability.

Jake: After all these years developing wheels, its exciting to see that we’re still improving the ride experience by delivering more speed and performance.

Further Reading:

Photo credits: Jered Gruber (2025 Tour de France); Ryan Hamilton (Cascade Mountain trail); Enve (wheels), all used with permission