Cranks, Racks and New Light Mounts

Good news: We’ve got cranks back in stock. They are being made in small batches right now. With the pent-up demand, the first batches will sell out quickly, but more are coming. Chainrings are also in stock in most sizes, with more on the way. If you’re planning to customize your gearing for real-world riding, but don’t want to give up the shifting performance and strength of the best racing cranks, we’ve got you covered.

Our forged cranks are superlight thanks to their minimalist 3-arm design and small bolt-circle diameter. More importantly, they’ve been optimized with Finite Element Analysis and some innovative manufacturing techniques, plus we use only the very best materials. That’s how Rene Herse cranks are the only cranks from a small maker that meet the most demanding EN ‘Racing Bike’ standard for fatigue resistance. And that’s why we cover our cranks with a 10-year warranty—twice as long as any other crank on the market.

For the shifting performance, we bench-marked our shifting ramps on the industry’s very best. Everybody who’s ridden our 9-12-speed cranks agrees that they shift better than almost any other rings out there.

Our popular UD racks are also back in stock. Often imitated, but never equalled, this versatile rack platform is available with stays for mounting to mid-fork eyelets, dropout eyelets, or canti posts. This means the rack can be used on most bikes with disc or canti brakes—provided the fork has a hole all the way through the crown. That hole is necessary to make the rack stiff and stable. Racks that bolt only to the front of the fork crown with an L-shaped strap will always be prone to swaying.

Beautifully made from ultra-strong CrMo tubing, the UD is one of the lightest racks you’ll find anywhere—just 221 grams for the disc-brake UD-1. It’s also one of the strongest. We test our racks’ load capacities on a torture machine, which mimics riding for thousands of miles over washboarded tracks at high speeds on narrow tires inflated to max. pressures. This means that the 10 kg (22 lb) load limit is what the rack can handle under the roughest conditions imaginable. In the real world, you’d ride wider tires if your roads are that rough, so that leaves a significant margin of safety… Since our racks are designed for the toughest conditions, we chrome-plate them so the finish won’t wear off like paint or powdercoat.

At Rene Herse Cycles, we ride our bikes hard, and we’ve found that small parts can make a big difference in real-world performance. Take our light mounts, for example. You can just bolt a bracket to your rack or fork and leave it at that, but there are better ways to mount lights.

One thing we’ve found useful is the ability to adjust the beam angle on the fly. We rotate our lights to a high position when descending mountain passes at high speed, so we can see far ahead even when the bike goes into a dip in the road. In the city or when there’s oncoming traffic, we rotate the light to a low position to avoid blinding other road users. (Blinding other traffic is not just impolite, but dangerous. Drivers who can’t see the edge of the road move closer to the center, giving us less room.)

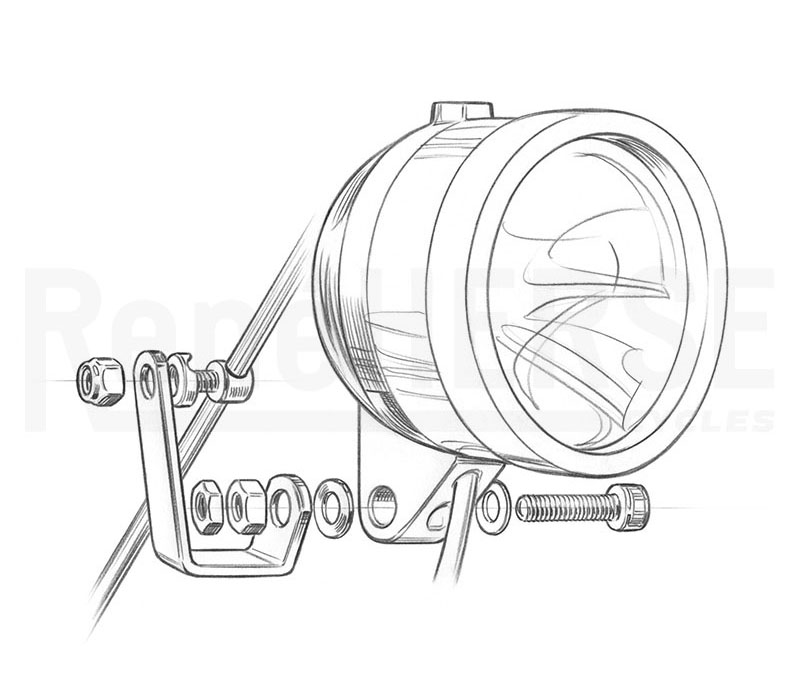

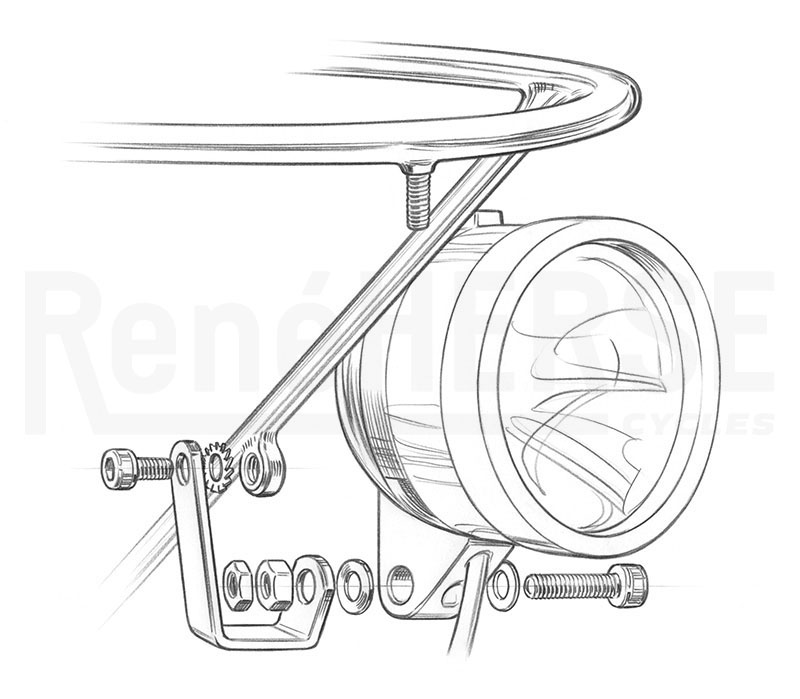

Instead of just bolting the light to the mount, we use a locknut. That way, you can tighten the mounting bolt ‘just enough’—so you can turn the light by hand—but thanks to the locknut, it’s never going to come loose. If you’ve adjusted the bearings of most hubs, you’re familiar with the idea of setting the right tension and then locking in the adjustment. With the Rene Herse light mount, it means you can adjust the beam angle on the fly, yet the light will never come loose.

Speaking of which, we’ve also designed the attachment of the light mount itself so that the weight of the light tightens the bolt/nut. The idea is the same as with your bike’s pedals, which have right- and left-hand threads so they won’t come loose. It’s just as important for your light mount: When you’re on an epic ride or race, having to stop every hour to tighten your light is a major distraction. In fact, a friend once scratched from an FKT attempt for a variety of reasons—one of which was a light mount that kept rotating no matter how much the bolt was tightened. These are small details, but they can make a big difference on the road.

Rene Herse light mounts are available in versions for eyelets (above) and for mounting on the struts of our UD racks (first drawing). We now offer the light mounts for right-side mounting, too. This is useful on bikes with disc brakes: Most generator hubs have the power take-off on the right side. (With rim brakes, you can usually mount the hub in any direction you want.) As before, the light mounts are also available for mounting on the left, so you can choose on which side you prefer to run your lights.

Speaking of small details, we commissioned the illustrations for the instructions from renowned French artist and illustrator Franck Stephan—who also did the illustration of our Nivex T-Shirts. Because small details make a difference in how much we enjoy our bikes—even when it’s just installing a light mount.

More Information:

- Rene Herse Cranks

- Racks and Light Mounts in the Rene Herse program

- Nivex T-Shirts