ETAs for Out-of-Stock Parts

The days of shortages in the bike industry are largely over—thankfully—but for small companies like Rene Herse Cycles there is still some catching up to do. Many of our products take a long time to make, with multiple steps, each done by a different supplier. That takes time. And sometimes, demand just is much greater than anticipated, and we simply run out of something everybody seems to want.

That’s what has happened with our new road tubeless 700C x 31 mm Orondo Grade tires. They received rave reviews from racers, shops and customers. They are easy to set up. They roll with the speed and comfort that you expect from a Rene Herse tire. As one shop put it: “This is the tire we’ve been wanting you to make for a long time.”

We ran out of Extralights first, and Standard casings followed soon thereafter. We still have the Endurance in limited quantities. The good news: More tires are already on the way to Seattle. We should have them in early March.

Rene Herse handlebars are also becoming increasingly popular. Riders are discovering that there is not need to live with hand pain or nerve damage, even when riding long distances on rough roads. Our handlebars are based on the experience of riding Paris-Brest-Paris, Unbound XL and many other long events. With their generous curves and truly anatomic shapes, Rene Herse handlebars provide comfort on all rides, from short jaunts to a café to continent-spanning adventures. They come in two shapes (Randonneur and Maes Parallel), two diameters (25.4 and 31.8 mm), and multiple widths (37 to 50 cm). That’s a lot of different models, and some of those are out of stock, while others are running low. More are already on the way to Seattle, just in time for the long (and short) rides of spring and summer.

The Rene Herse stem is one of the most iconic parts, period. “A hole surrounded by aluminum,” is how one of his riders described it. Even by today’s standards, the Rene Herse stem is superlight (160 g for 90 mm length). It’s also super-strong, with zero reported failures in decades of hard use. And it’s beautiful. The current version is updated with titanium bolts. It clamps onto a tube that is brazed (or glued) into the steerer tube, leaving room inside for our light switch.

The Rene Herse stem is a labor-intensive component to make. First we machine the stem blank. Then the inside of the slot is polished. (It’s no longer accessible once the brake cable stop is in place.) The brake cable stop come next. It’s pressed into the stem blank. Then we drill the hole for the cable housing and brake cable. The the stem goes back to the polisher to buff the outer surfaces to a mirror shine. The first batch of stems sold out quickly, but a new production run is almost finished. We hope to have them by April.

SON generator hubs and lights are also increasingly popular. They’ve long been standard equipment for randonneurs, but now we see them more and more on bikepacking bikes. Not having to worry about charging your lights is a big plus. So is not having to worry about your generator hub failing in the middle of nowhere. The clever pressure compensation system—unique to SON hubs—prevents moisture from getting sucked into the bearings when the air inside the hub contracts as the temperature goes down. (There is a lot of air inside a generator hub, so this is a real problem with other hubs.) And SON hubs have the lowest resistance of all generator hubs: When you turn on your lights, the difference in speed is almost imperceptible.

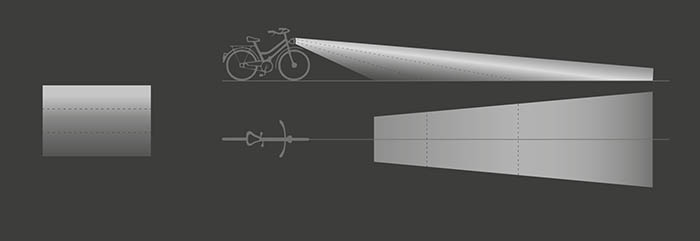

You do notice the Edelux headlights as soon as it gets dark. Their sophisticated optics project more light into the distance, where the beam hits the road at a shallower angle. That’s key for getting even illumination far into the distance. Edelux headlights allow us to ride at night with the same speed and confidence as during daytime. If there is a game changer in long-distance cycling, it’s these hubs and lights. Some models are out of stock, but we are expecting more in early March.

Wool tights make a huge difference during cold and wet-weather rides. If your feet are cold, it’s usually because your legs radiate off too much heat, and not enough arrives at your feet to keep them warm. Wool has amazing insulation properties—even when it gets wet—and it adjusts to a wide range of temperatures. Unfortunately, all wool tights on the market are mostly synthetic, with less than 1/3 wool content. So we made our own, made from 90% of the finest Merino wool. (The 10% synthetics make sure these keep their shape even after many wash cycles.) These are made in Europe, and delivery is spotty. Currently, the next batch is scheduled to arrive in time for the autumn cool-weather rides.

The Rene Herse cyclotouring knickers have many fans. There are times when it just doesn’t feel right to enter restaurants, shops or museums dressed only in tight-fitting cycling shorts. The sophisticated cut of these knickers doesn’t inhibit performance—above I’m wearing them in Paris-Brest-Paris.

The intricate nature of these knickers makes them very hard to sew. The small workshop in Seattle that used to make them for us is busy with other, simpler projects. So there will be no more until we find a new supplier.

This is a problem with many of our products: Their superior performance also makes them very hard to manufacture. We are a small customer for most of our suppliers, yet we demand the highest quality standards.

Take our cranks, for example. The small bolt circle means you can run any chainring combination from 24 to 52 teeth. Three spider arms are all you need, and not having four or five saves significant weight. These features require much tighter manufacturing tolerances to prevent the chainrings from wobbling. (More arms and a bigger bolt circle will pull even a wobbly chainring into shape.)

Making cranks to these specifications is difficult, but ‘difficult’ has never scared us. It just means we (and our suppliers) need to work a little harder. That’s why restocking often takes a little longer. We are happy that all crankarms and chainrings (except one size) are now back in stock.

Since we use these parts on our own bikes, we won’t compromise on quality. And we are in as much of a rush as our customers to complete our projects and get on the road. Thank you for your patience!

Click on the images for more information about these parts.