Myths Debunked: Higher Tire Pressure is NOT Faster

This used to be one of the first things you learned as a cyclist: If you want to go fast, make sure your tires are pumped up to the maximum pressure. The harder your tires are inflated, the faster they roll.

We now know that this is not true. The realization that tire pressure does not affect performance is the key to the revolution that has swept through the cycling world in recent years. Without this new-found knowledge, all-road bikes and their supple, wide tires would make no sense at all. Here is how it works.

Shortcut: If you just want to know how much to inflate your tires, our tire pressure calculator allows you to optimize your tire pressure for the lowest rolling resistance.

Tire resistance is determined by two factors:

Hysteretic Losses: With each turn of the wheels, the tires flex. You can see that in the photo above: Both tires flatten where they touch the road. Flexing the tires takes energy – imagine squeezing a tennis ball. Energy on a bike can only come from one source: the rider’s power output. Reduce the energy lost to flex, and you’ll go faster.

The easiest way to reduce this energy loss: Inflate the tires more, and they’ll flex less. Less flex means less energy is converted to heat as the tire casing deforms under the weight of bike and rider.

You can also reduce the energy losses by making the tire casing easier to flex. A supple casing is easier to flex than a stiff one, so it absorbs less energy for the same amount of flex. Imagine squeezing a marshmallow instead of a tennis ball.

So if we’re only looking at the energy lost inside the tire, we want a tire that is supple and runs high pressures. That means we have to make it narrow. (There’s a link at the bottom that explains why wide tires can’t be supple and have a high pressure rating.)

Summary: The best way to reduce hysteretic losses is to use supple tires, make them narrow, and inflate them hard.

That was the accepted wisdom when we started looking at tire performance, way back in 2006. It’s not incorrect, but it overlooks a second factor that also affects how fast a bicycle rolls – and tire pressure works the opposite way there.

Suspension Losses: As the bike vibrates, energy is lost. Most of that energy is absorbed in the rider’s body, as soft tissues rub against each other. Decades ago, the U.S. Army studied tank seats and found that the discomfort we feel from vibrations is caused by friction between our body’s soft tissues. This friction consumes energy that is turned into heat. (Rub your hands against each other to see how friction creates heat.) The more uncomfortable the vibrations, the more energy is lost.

Mountain bikers have known for a long time that bouncing makes your bike slower. The fastest mountain bike is the one that absorbs shocks best. Road cyclists used to think that we had to ‘tough it out’ to go fast. We endured the discomfort of narrow high-pressure tires because we thought that they rolled faster. We thought that pavement was too smooth for suspension losses to matter.

At Rene Herse Cycles, we started to test the performance of tires on real roads in 2006. At first, we also assumed that higher pressures rolled faster. What we wanted to know is: How much faster? So we tested various tires at different pressures, on real roads, with a rider on the bike…

Imagine our surprise when we found that in the real world – on real roads – tires perform very differently. We tested numerous tires, with two different methods (roll-down and power meter), and always found the same: Higher pressures don’t make tires faster.

What happens is this: As tire pressure increases, the tire flexes less, and the hysteretic losses go down. However, the tire also vibrates more, and the suspension losses go up. The two roughly cancel each other, and that is why higher pressures aren’t faster.

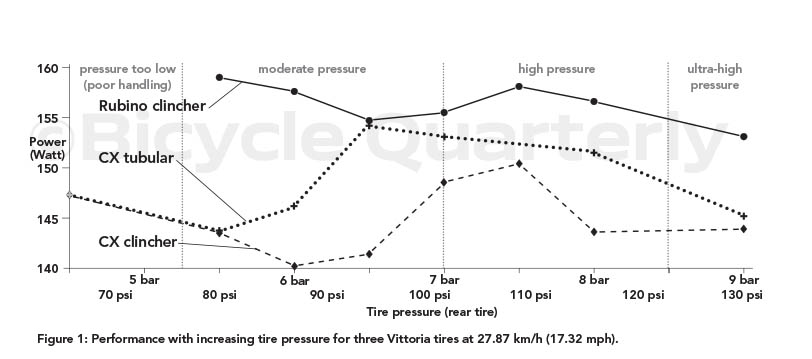

Above is the real-road data for three Vittoria 700C x 25 mm tires with a 160-pound rider. We tested on brand-new, ultra-smooth asphalt. You can see that performance doesn’t automatically get better if you inflate the tires harder. In fact, the most supple tires in this test (Vittoria CX—we did this test years ago when they were these were the best pro-level tires) roll fastest at moderate pressures. The relatively stiff Rubino seems to get faster at ultra-high pressures, but it’s just as fast at 95 psi.

Before we continue, it’s important to mention that we made sure these results are statistically significant. This means that we are seeing real differences in performance, not just ‘noise’ in the data. (Our data analysis is performed by Mark Vande Kamp, who has a Ph.D. with a minor in statistics.)

The graph shows a few more things:

- Really low pressures make a tire slow, because it flexes way too much: the hysteretic losses are huge. The extreme is a totally flat tire – extremely slow. At some point, the tire has enough air to avoid excessive flex. Above this ‘break point,’ hysteretic and suspension losses start to balance each other.

- Hysteretic and suspension losses are non-linear, so they balance differently for different tires and different pressures.

- CX Tubular: A tubular tire sits on top of the rim, so it can flex around its entire circumference. It can run at very low pressures without excessive flex. The fastest pressure is relatively low (80 psi).

- CX Clincher: A clincher rim constrains the tire around about 1/3 of its circumference, so a little higher pressure is needed to avoid excessive flex. It’s fastest at 87 psi.

- Rubino Clincher: The Rubino’s stiffer casing is harder to flex. The hysteretic losses for the same amount of flex are higher. The stiffer casing also transmits more vibrations, so low pressure doesn’t reduce the suspension losses to the same amount. This means that it has its lowest resistance at a higher pressure than the more supple CX (95 psi).

- All three tires roll slowest at moderately high pressure: The tire is already too hard to absorb vibrations, so suspension losses are high. However, the casing still flexes, so hysteretic losses are also high. It’s better to run low or very high pressures, at least on the very smooth asphalt of our test track.

Summary: On real roads, even smooth ones, higher pressures don’t roll faster.

We tested many, may tires and always found the same: Running higher pressures doesn’t make you faster. I wish we had done this testing when I was still racing. Back then, I ran 21.5 mm tubulars at a bone-rattling 130 psi.

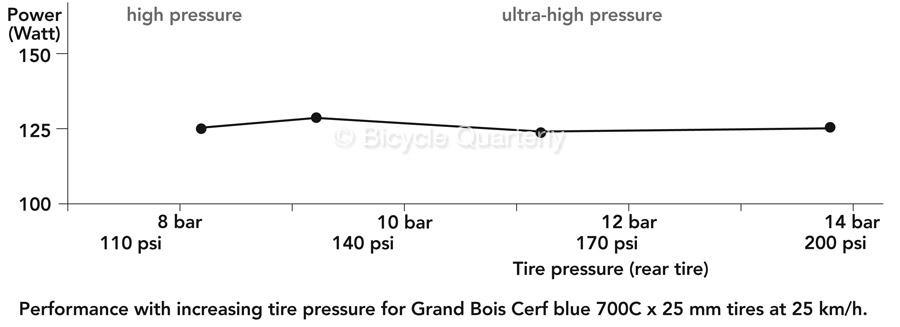

What if we go to really high tire pressures? We ran a 25 mm tire all the way up to 200 psi, and it didn’t get any faster. (Don’t try this at home, it’s not safe to run these tires at that pressure!)

The above results were on ultra-smooth pavement. Does the road surface affect the pressure at which a tire rolls fastest?

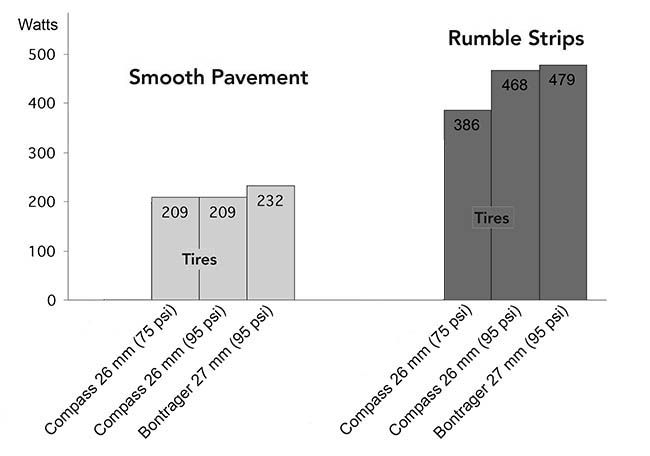

To test an extreme case, we ran various tires on rumble strips, which are a good stand-in for cobblestones. (Unlike real cobblestones, rumble strips are very regular, so we could obtain repeatable results.) We also tested each tire on the smooth pavement right next to the rumble strips. The speed for this test was higher, that’s why more watts were needed even on the smooth pavement.

On the smooth pavement (left), the Compass/Rene Herse 26 mm tires roll as fast at 75 psi as they do at 95 psi. This confirms what we’d found before: On smooth roads, inflating your tires harder doesn’t make you faster.

On the rumble strips (right), higher pressure was slower: The 26 mm Compass/Rene Herse tires used 20% more energy at 95 psi than they did at 75 psi. And the stiff Bontrager tires were always slower than the supple Rene Herse tires.

Summary: On really rough surfaces, higher pressures roll slower. That’s also the main reason wider tires roll faster on rough surfaces: They can handle lower pressures.

So now we know that higher pressures don’t make your bike faster – whether on smooth asphalt, on rough surfaces like cobblestones, or anywhere in between.

On smooth roads, with supple tires, the break point – where tire pressure is high enough for optimum performance – is close to the point where the tire becomes unrideable. If you go too low with your tire pressure, the sidewalls collapse under hard cornering. At that point, the tires flex so much that they also slow down. That’s on smooth roads. On rough surfaces, there is no break point – the tire bottoms out before its performance deteriorates.

Conclusion: If you want to go fast, you need supple tires. That is all. Pumping them up harder won’t make you faster. On rough surfaces, it actually makes you slower.

When we saw these results, we realized that this could revolutionize bicycles: If we didn’t need to high pressure to go fast, we could make wide tires with supple casings, run them at (relatively) low pressure, and still roll as fast as we did on narrow ‘racing’ tires. With these wide, supple tires, we could go on roads and trails that wouldn’t be much fun on a traditional, narrow-tire racing bike.

We envisioned a new breed of bike – racing bikes with ultra-wide, supple tires – and we created a new word for them: ‘Allroad Bikes’ (still without a hyphen). That was way back, in 2006. At first, nobody took us and our test results seriously. It was just too far out there.

We were undeterred, and we set out to turn this new type of bike from a dream into reality. The first step was to make the tires we needed for these all-road bikes. First we worked with other manufacturers, but in order to get exactly the tires we wanted, we introduced our own tires in truly wide widths (above). It’s taken the bike industry a little while to get on board, but now our ideas are generally accepted: All-road and gravel bikes are the most important segment in the performance bicycle market.

In fact, even road bikes have benefitted from our research. These days, even pro road racers roll on tires that would have been laughed at just a decade ago. How much I wish I had the new tubeless-specific Rene Herse Arondo Grade tires (above) when I was racing, instead of those bone-rattling narrow tubulars! I would have been faster – much faster – and also much fresher as I approached the finish line. Of course, we all raced on the same tires back then, so it was a level playing field.

What it all boils down to is simple: We used to think that we had to trade comfort for speed. Now we know that discomfort not only is unpleasant, it actually slows us down. Put more simply:

Comfort = Speed

And that means wider tires, lower pressures, and more fun.

Tire Pressure Calculator:

- Our tire pressure calculator helps optimize your tire pressure for the lowest rolling resistance.

- Why wide tires cannot be supple and have a high pressure rating.