Myths Debunked: Tread Patterns Do Matter, even on the Road

To celebrate 15 years of Bicycle Quarterly, we are examining myths in cycling – things that we (and most others) used to believe, but which we have found to be not true. Today, let’s look at tire tread: Tread patterns matter – they can make a difference – even on the road.

“Bicycles don’t hydroplane,” declared some experts many years ago. “Hence, tire tread patterns don’t matter on the road.” The first part is true – even wide bicycle tires are too narrow to lose traction due to hydroplaning – but tire tread doesn’t only serve to evacuate water from the tire/road interface.

In fact, the tread of bicycle tires has other purposes. I once cycled on the polished stone that surrounded a college library, and I was surprised by the lack of grip: I crashed. Even though I was unhurt, I learned the hard way that the coefficient of friction between our tires and the rocks that make up the road surface isn’t very high. Yet we don’t crash on roads made from the same rocks, but in the form of rougher aggregate in pavement. What happens is that tire and road interlock to create grip.

If our grip came only from pure friction, the size of the contact patch wouldn’t matter. Physics tells us that if you double a tire’s width, it will be pushed into the road surface with half as much force – the two cancel each other. Yet race cars run ultra-wide tires because they provide more grip. What is going on?

Tires interlock with the road surface. Imagine each little surface irregularity like a spike that pushes into the tire. The wider the tire, the more surface irregularities it touches; hence it has more grip. A softer tire also has more grip because the road surfaces pushes deeper into the tire. That is why the tires of race cars use very soft rubber, and why wider bicycle tires at lower pressures offer more grip than narrow ‘racing’ rubber at higher pressures.

There is another way to increase the interlocking between tire and road: provide edges on the tire that ‘hook up’ with the road surface irregularities. Each edge provides a point where a road irregularity can hook up. The more edges you have, the better the tire hooks up.

This isn’t a new idea – back in the days when rubber compounds were less grippy, all racing tires used treads that were similar to the Rene Herse tire above. I often wondered about these ubiquitous tread patterns, until I found the answer in Bike Tech, a long-defunct newsletter about bicycle technology. Under the headline “The Importance of Real-World Results,” a Michelin engineer described the interlocking mechanism, and explained that, especially in the wet, interlocking is what gives a tire much of its grip.(1) If the surface is ‘greasy’ when it first rains after a long period of dry weather, friction is even less, and the interlocking is even more important.

That matches my experience. In theory, the friction between road and tire should be less than half when it’s lubricated with water, and yet we can corner at about 2/3 of the ‘dry’ speed in the wet – at least on good tires (and when the road is just wet, rather than greasy).

This doesn’t mean that the rubber compound of the tire tread doesn’t matter – it’s a crucial element in making the tire grip on dry and wet roads. At Rene Herse, we are excited to use some of the grippiest, yet long-wearing, rubber in the tire business. That way, we can optimize the grip of our tires in every way.

The result speaks for itself: The photo shows me cornering hard on a streaming wet road, yet I wasn’t taking any risks during that descent. There aren’t many tires I’d lean over that far in those conditions!

Why don’t cars or motorcycles use ribs to interlock with the road? They have too much power. A drifting Moto GP rider (above) would just shred those ribs. Motorbikes and cars also are heavy enough to push their tires into the road surface, where bicycles tend to skitter across the surface.

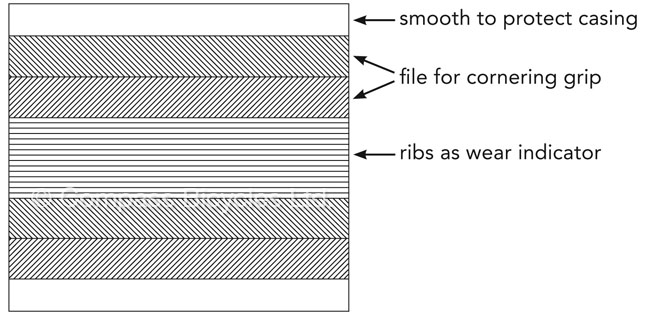

On a bicycle tire, distinct parts of the tread serve different purposes.

The center tread doesn’t matter much – you are going straight when it touches the road. This is also the only part that wears significantly, so we put some fine ribs on our Rene Herse tires that act as wear indicators: When they become completely smooth, then your tire is at about half of its life expectancy.

Furthermore, some tests have found evidence that a very fine tread pattern can make the tire faster, because it conforms more easily to micro-irregularities of the road surface and reduces the vibrations of the bike. So it makes sense to have a fine tread in the center.

The shoulders of the tires are important for cornering traction. This is where we put our ‘file’ or ‘chevron’ tread pattern for optimum grip. There is no magic to this, and these ribs aren’t directional – the point is just to have as many as possible to hook up with the road surface, but keep them large enough that they don’t just squirm out of the way.

Finally, you have the edges of the tire, which usually don’t touch the road – bicycles simply can’t lean over as far as a Moto GP racer. Here, the tread only serves to protect the tire’s casing from rocks and other obstacles. This tread can be smooth.

It’s all quite logical, and easy to experience on the road. Then why don’t all tires have a tread pattern that is optimized for grip? I suspect it’s hard to replicate the interlocking effect in the lab. But when you ride on real roads, you’ll notice the difference!

Update 11/17/2020: We’ve just published our new book ‘The All-Road Bike Revolution’ with all the research that has changed cycling in recent years. Find out why wide tires can be fast, how to find a frame that optimizes your power output, and how to get a bike that handles like an extension of your body. More information is here.

Notes: (1) Aaron, M., 1988: Importance of Real-World Results. Bike Tech, October 1988, p. 5.