SKF Bottom Brackets Back in Stock

Bottom brackets are almost invisible, and you only notice them when something goes wrong. When the bottom bracket in my Firefly started to bind after just a few hundred miles, I put in an SKF, and that was the last I thought about it. When the bike was overhauled, the BB was spinning as smoothly as ever. That is how it should be!

How does the SKF last so much longer than other bottom brackets? SKF is a world leader in bearings, and they’ve applied all their technology to these bottom brackets. The two biggest advantages are larger bearings and better seals.

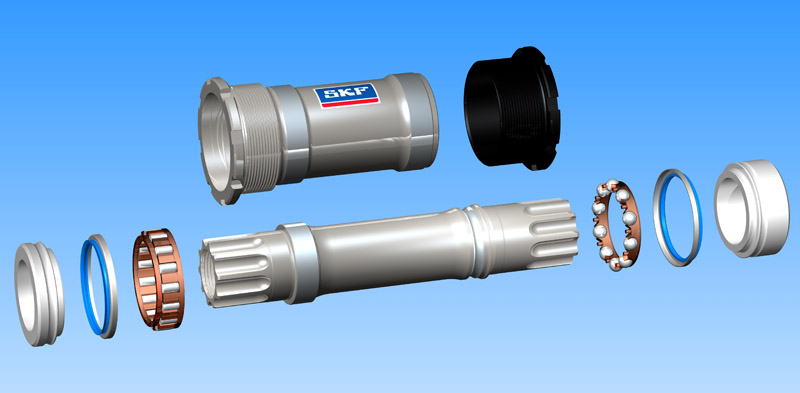

Let’s look at the bearing size first. SKF runs the bearings directly on the spindle and on the shell of the cartridge (above). That way, there is enough room for large ball bearings that can handle the high torque and low rpm of a rider’s pedaling, which is really tough on bearings. On the driveside (left side above), the SKF bottom bracket uses even stronger roller bearings to handle the extra force of the chain.

Most other bottom brackets use premade bearings (also called ‘cartridge bearings’ or ‘sealed bearings’), usually the 6903 size shown above. Using a premade bearing is much easier, as you don’t have to grind and polish the bearing seats. Instead, you simply press the bearing’s inner race onto the spindle and the outer race into the shell. The problem is that the extra bearing races waste space, and then you no longer have room for properly-sized ball bearings.

Bottom bracket shells were originally designed for cup-and-cone BBs that run the bearings straight on the spindle and the cups. They started with 1/4″ balls (6.35 mm) and sized everything up from there, without wasting a single millimeter. Most bottom bracket shells still are that size, even though cup-and-cone BBs now are rare.

When you use premade bearings, you lose about 1.5 mm on each side, plus a little bit more because the sleeve needs some room inside the BB shell. As a result, the largest balls you can fit are 2.8 mm in diameter, less than half the ‘normal’ size. These small balls have a much lower load rating, and they’ll also wear out faster.

The other big issue is that the premade bearings don’t have good seals. They are sometimes called ‘sealed bearings,’ but those black or red rubber seals are intended only as dust shields for indoor applications. They aren’t waterproof at all. You’ll never see a bearing like that exposed on a car, and yet even high-end bottom brackets put nothing but a rubber shield between your bearings and the gritty outside world.

The SKF bottom brackets have labyrinth seals that really do keep moisture out. Once, I cut open an SKF cartridge that I had used on my Urban Bike for a full year of rainy Seattle commutes, and the grease inside was fresh and clean. These seals are truly high tech, and SKF even patented them, because they were designed specifically for this application.

As a result of all this quality, we can offer these bottom brackets with a 10-year warranty that includes the bearings. (Actually, we limit the warranty to 10 years or 100,000 km, whichever comes first.) For most riders, one of these SKFs will be the last bottom bracket they install in their bike, and it’s certainly been that way for me.

SKF had stopped making these bottom brackets, and for a while they were unavailable. We are glad that we now can offer them again in all sizes, with British, Italian and even French threading, as well as in an ISIS version, as a world-wide exclusive from Compass Cycles. Click here for more information about SKF bottom brackets.