Tires

Technical Information

Which Rene Herse tire do you recommend for me?

Read our full guide on how to select your Rene Herse tires, with information on how to choose width, casing and tread pattern.

How wide a tire should I run?

As a general rule of thumb, wider tires offer more comfort, more grip and the same speed as narrow ones. Go wider, and you won’t regret it. Conversely, it’s not necessary to squeeze the widest possible tire into your frame. Supple casings make a bigger difference than a millimeter or two in width. When in doubt, go down a size rather than risk that your tire will rub on your frame or fork. Read more…

Which tread pattern do you recommend?

For paved roads and smooth gravel, our all-road tread with its fine ribs is the best choice. It combines excellent performance and grip on pavement with surprising traction on loose surfaces – the supple casing allows the tire to grip the surface much better than a stiffer tire.

Our dual-purpose knobbies offer supreme traction on dirt, mud and even snow. They are also a great choice for riders who prefer a more aggressive tread on loose surfaces. On pavement, our knobbies will surprise you with their low rolling resistance and excellent cornering grip. They’re the perfect tire for adventures where you don’t know what lies ahead.

Why doesn’t Rene Herse offer semi-slicks or tires with shoulder knobs?

Semi-slicks and shoulder knobs usually result in poor compromises. They perform like slicks on gravel and dirt (where you can’t lean over far enough to engage the shoulder knobs) and like knobbies on pavement (where they break away suddenly as you go from slick to knob when leaning into a turn). Instead, we’ve refined our knobby tires so that they roll and corner as well as slicks on pavement, while offering the off-road grip of knobbies. In other words, with our knobbies, you don’t have to compromise between speed on smooth surfaces and grip when the going gets rough. Click here to read more…

Which casing is best for me?

Rene Herse tires are available with four different casings for different riding styles and conditions:

• Standard: The supple casing that has made our tires famous: comfortable and fast, yet it’s also strong to withstand considerable abuse. Available on all models (except 26″ x 1.25″ Elk Pass).

• Extralight: Ultimate in speed. Ultimate in comfort. Ultimate in light weight. An extremely fine and supple casing that you’ll otherwise find only on hand-made tubulars. Available on all models.

• Endurance: The same extra-fine threads as our Extralight casing, but pushed closer together for a denser weave, and with an additional protection layer on the sidewalls and under the tread. Excellent resistance against punctures and abrasion, while keeping most of the speed and comfort that has made our tires famous. Click here for the tires that are available with the Endurance casing.

• Endurance Plus: Thicker threads for even more strength and resistance against cuts and abrasions, plus an even stronger protection layer on the sidewalls and under the tread. A tire for durability above all, yet still surprisingly fast. Click here for the tires that are available with the Endurance Plus casing.

• All models have the same tread rubber and thickness, so they have the same wear resistance.

• For more information about our casings, check out this Journal post.

What does the noise-cancelling knobby tread do?

Our revolutionary noise-cancelling tread places the knobs in a way that the frequencies of the knobs hitting the ground cancel each other. On most surfaces, our noise-cancelling dual-purpose knobbies roll as quietly as our smooth all-road tires. Click here for the tires that feature noise-cancelling knobby treads.

TPI of the different casings?

We – and many other makers of high-end tires – don’t list TPI (threads-per-inch), because it’s not a good measure of how supple a tire is. What matters is how fine the threads are, how much rubber covers them, and other factors that are harder to measure. Read more…

How wide a tire will fit my bike?

Check out our illustrated instructions for measuring clearances on your bike.

What is the actual width of Rene Herse tires?

The actual width is listed in the ‘Tech Specs’ for each tire. Our tires are made by hand, and rubber is flexible, so the actual size can vary a little from batch to batch. Remember that the suppleness of the casing is more important for comfort and speed than a millimeter or two in width. When in doubt, choose a size smaller, rather than risk have your tires rub on your frame or fork. Read more…

Are Rene Herse knobbies wider/taller than the smooth all-road tires?

The dual-purpose knobbies aren’t any wider: The knobs don’t stick out beyond the casing. They are about 2 mm taller than the equivalent smooth all-road tires, because the knobs are a little taller than the all-road tread. Remember that if you plan to run knobbies on a bike with fenders, you’ll need very generous clearances, because knobbies are more likely to pick up larger stones or branches that can get stuck in the fender.

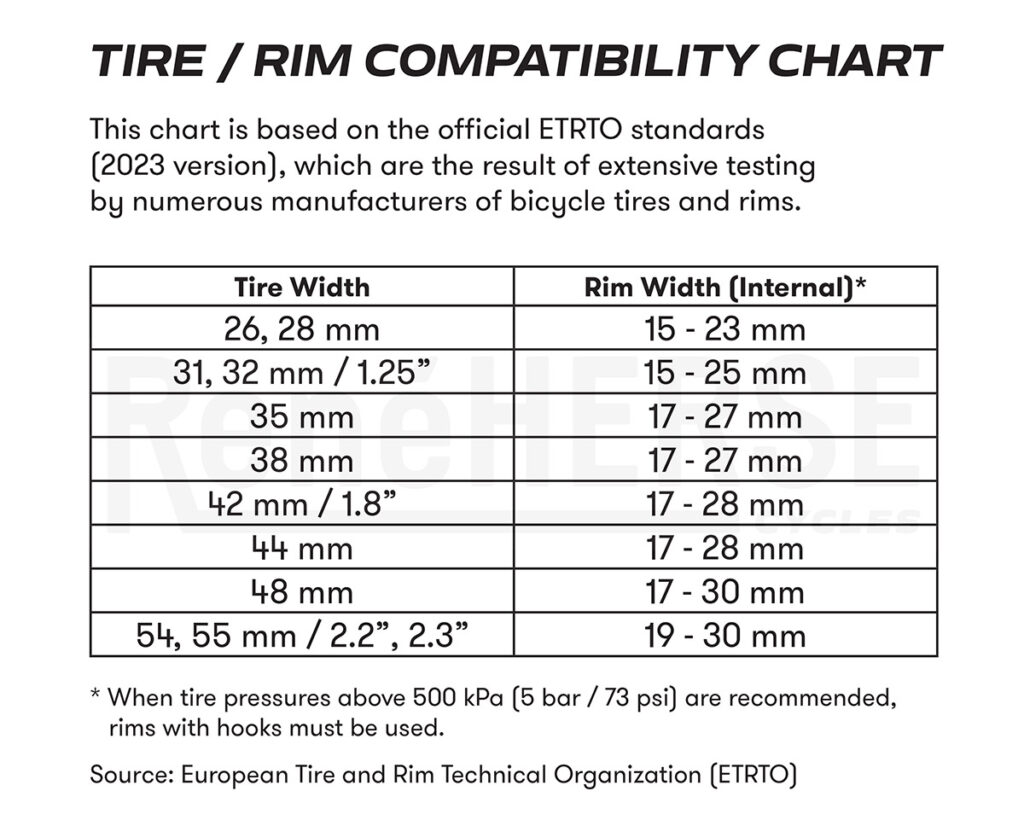

Rim width?

Please refer to the official ETRTO / ISO tire and rim compatibility chart (below). If the rim is too wide, the tire can blow off, because it doesn’t properly engage with the rim’s sidewall.

Narrow tires (≤30 mm): To allow optimizing the aerodynamics of racing bikes, the ETRTO chart is pushing the limits of how wide the rim can be. If all dimensions of your rims are perfectly to spec—usually the case on high-end rims—that’s no problem. If you are running rims that came stock on your bike, it’s safest to keep the rims at least 20% narrower than your tires (≤21 mm rims for 26 mm tires; ≤23 mm rims for 28 mm tires).

You may have heard that matched rim and tire widths make the tire sidewalls more vertical, so they bear more of the bike and rider’s weight. This may work with stiff sidewalls and allows running a lower tire pressure, but also decreases shock absorption and comfort.

With supple tires, almost the entire weight is supported by the air pressure of the tires. Whether the sidewalls are vertical or bulge makes very little difference. Read more…

Approved rims?

Our tires are designed to the ETRTO / ISO standards. All rims that meet these standards are fine to use with Rene Herse tires. Rene Herse tires can be used with hookless rims or with rims that have hooks. Read this entry in the Rene Herse Journal for more information and a list of rims with their actual measurements.

Hookless rims?

Rene Herse tires can be used on hookless rims if the rims are of high quality and meet ETRTO / ISO standards. The hook on most rims helps hold the bead in place, making it more difficult for the tire to blow off the rim. Without a hook, the tire/rim fit must be very good to ensure that the tire cannot blow off. High-quality carbon rims are hookless, but also control the diameter of the bead seat very closely.

We have worked with Enve and Zipp to test the fit and safety of our tires on these companies’ carbon rims. These rims are fine to use with all Rene Herse tires. Other high-quality rims work as well. More important than the hook are the dimensions of the rim. If they meet ETRTO / ISO standards, they are fine to use with Rene Herse tires. Read this entry in the Rene Herse Journal for more information and a list of rims with their actual measurements.

My rims say “Tubeless Tires Only.” Can I run non-tubeless Rene Herse tires on these rims?

Yes, all Rene Herse tires have a tubeless bead, even if not all are officially tubeless-compatible. That means you can run non-tubeless Rene Herse tires on all rims, even those that say “Tubeless Tires Only,” as long as you use inner tubes. We have worked with the engineers at Enve and Zipp and tested all Rene Herse tires on their wheels for thousands of miles, without encountering any issues. Make sure your rim width is appropriate for the tires you want to run (see above).

Optimum Pressure?

The optimum tire pressure depends on your tire width, your weight, the terrain and your riding style. Determine the best tire pressure by experimenting what feels right. Our Tire Pressure Calculator shows you at what pressure your Rene Herse tires have the lowest rolling resistance. Use that as a starting point for finding the right tire pressure for your bike and your riding style.

Minimum Pressure?

The minimum pressure of your tire depends on your weight, so we don’t list a minimum pressure for Rene Herse tires. More information about minimum pressure is here.

Which Rene Herse tires are tubeless-compatible?

All tubeless-compatible Rene Herse tires have ‘TC’ in the product name, for example: 700C x 48 mm Oracle Ridge TC Tire. The product description also lists whether the tire is tubeless-compatible or whether it requires tubes.

Tubeless or tubes?

Many Rene Herse tires are tubeless-compatible. The packaging for these tires says: “Tubeless Compatible.” This means they can be set up tubeless (with a sealant) or used with tubes.

Tubeless setup reduces the risk of pinch flats, which can be useful when riding at high speeds across rough terrain. Disadvantages of tubeless mounting are the more difficult setup and closer rim tolerances required to prevent blow-offs. As to speed, the sealant inside tubeless tires cancels out the gains from eliminating the tube: Tubeless tires roll as fast as tires with tubes.

If you are leaning toward tubeless tires because you are concerned about punctures, you can use sealant inside your inner tube. (The tubes we sell have removable valve cores.) More information is in our Tubeless Tire FAQ.

How much sealant?

With supple tires, sealant is required to seal the tire against the rim. Make sure to use enough sealant. We recommend the following amount of sealant, based on the width of your tires:

- 25 – 32 mm: 60 – 90 ml (2 – 3 oz.)

- 35 – 42 mm: 90 – 120 ml (3 – 4 oz.)

- 44 – 55 mm: 120 – 150 ml (4 – 5 oz.)

Make sure to replenish the sealant at least once a month, as it tends to dry out.

Are Rene Herse tires suitable for heavy rider and/or tandems?

We’ve ridden many thousands of miles on our tandems with Rene Herse tires. As long as you can get enough pressure for your weight without exceeding the maximum pressure rating, there is no weight limit on Rene Herse tires. Wider tires require less inflation, so they are better suited for heavy riders or tandems. Check our Tire Pressure Calculator for more information.

Ted King’s Tips for Choosing Tires

Few riders have as much experience riding and racing all over the world as Ted King. Read what the ‘King of Gravel’ says about choosing his tires for different events, terrain, etc.