Rim and Tire Standards

Standards exist mostly to ensure interchangeability of parts. If you need replace one of the bolts that attach the bottle cages on your bike, you can go to any hardware store in the world and buy an M5 bolt. Unless it’s specified otherwise, the threads will have a diameter of 5 mm and a pitch of 0.8 mm. The head will match an 8 mm hex or a 4 mm Allen wrench (or a 3 mm if it’s a cap head). It doesn’t matter whether you’re touring in the U.S., Japan, Europe, or almost anywhere else in the world, you’ll be able to replace that bolt. (There are also standards for the bolt’s strength, which are important if you replace a highly-stressed part, like a handlebar clamp bolt on your stem.)

These standards are defined by different organizations. One of the most important is the International Standards Organization (ISO). There’s also the European Tire and Rim Technical Organization (ETRTO) that defines the standards for tires and rims used all over the world, for cars, motorcycles and bicycles. If you need a new tire for your car, you know that a 205/60 R 15 tire can be replaced with any tire that has the same designation.

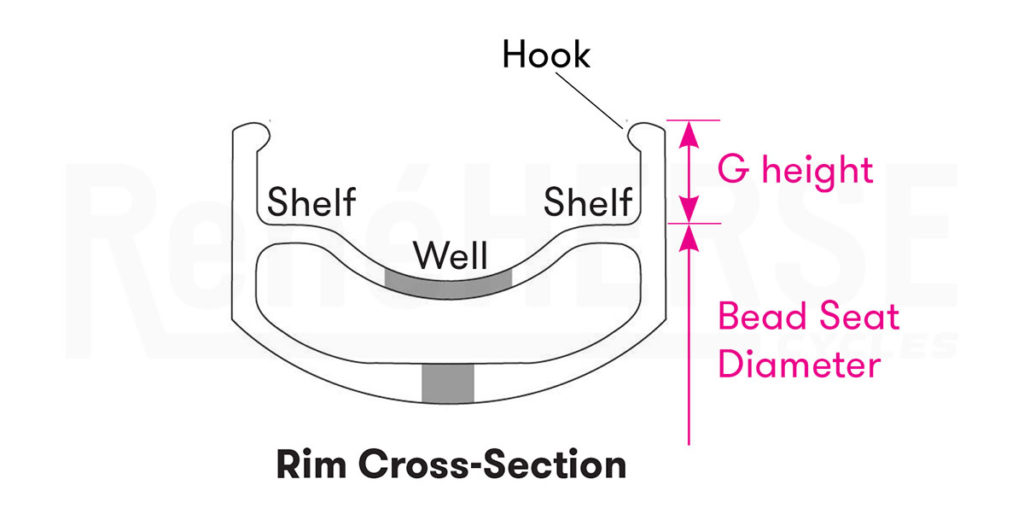

The same applies to bicycles. A 38-622 mm tire – what many of us still call a 700C x 38 mm – will fit on any 622 mm (700C) rim that is made to the ERTRO standards and that is between 17 and 27 mm wide. (Those widths are also defined by ETRTO standards.) The actual standards are voluminous documents that specify everything from how wide a tire you can fit on a given rim, how tall the hook needs to be (G height), all the way to the radius at the transition from sidewall to well.

The rim makers actually have the easy part of the job: Their rims just need to match the ETRTO standards. Then it’s up to the tire makers to design tires that fit on all rims that meet these standards. It makes sense: Rims are made from metal or carbon, so their dimensions are easy to specify. Tires are flexible, and it would be difficult to make standards for all different types of tires. Plus the ETRTO isn’t in the business of designing tires—they just provide a baseline rim design on which all tires have to work.

If a component doesn’t match the standards, all bets are off. If the deviation is small, it may work, but there’s no guarantee. For high-performance parts, meeting the standards is especially important. A steel bolt can stretch a bit if the thread pitch is slightly off, but a bolt made from titanium or aluminum may break.

The same applies to supple high-performance tires. A stiff tire may stay on an undersized rim, because it holds its shape even without proper support from the rim. A stiff sidewall effectively pushes the tire onto the rim. A supple tire doesn’t have that support, and it’s essential that the tire bead has a good fit on the rim shelf. If the rim is undersized, the tire may blow off.

What does that mean in practice? The most relevant parts of the current rim standards for performance bikes are:

Bead Seat Diameter (BSD; diameter of the rim at the shelf where the tire bead sits):

- 26″ : 559.0 mm

- 650B: 584.1 mm

- 700C: 621.95 mm

- Tolerance: ±0.5 mm

- Rims for tires with tubes: standards for 26″ and 650B are ~0.5 mm smaller. (700C is the same for tubed and tubeless.)

G Height (sidewall height on the inside of the rim):

- Tubeless rims with hooks: 5.5 mm

- Tubeless rims (hookless): 6.0 mm

- Tolerance: ±0.5 mm

These are the current (at the time of writing) 2021 standards — much simplified from the past. One thing to remember, too, is that adding tubeless rim tape reduces the G height by 0.2 mm and adds 0.4 mm to the BSD.

What this means in practice:

If the BSD is too large, the tire will be hard or impossible to seat. If the BSD is too small, the tire will fit loosely and can blow off the rim. If the G height is too small, there is not enough support for the tire bead, and the tire can blow off the rim.

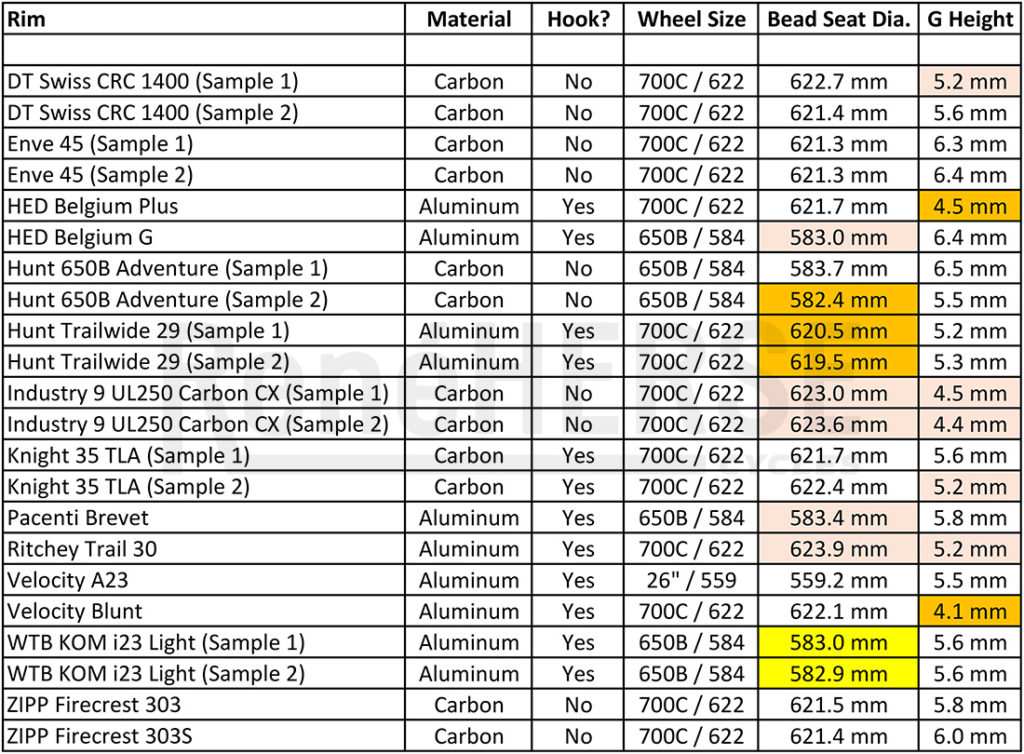

Manufacturers rarely list the Bead Seat Diameter and G height of their rims. The assumption is that they are made to the relevant ETRTO standards. At Rene Herse Cycles, we test a lot of rims to check compatibility of our tires with different rim shapes and models. Below are the measurements of some rims we’ve measured recently. The rims were measured without tape. Once you add a layer of tubeless tape, that increases the BSD by 0.4 mm and lowers the G height by 0.2 mm.

Tire fit depends on both BSD and G height. If the BSD is larger, the tire will fit tightly on the rim, and the G height can be a little smaller. We see this with some carbon rims: The outer diameter of carbon rims is determined by the mold and doesn’t vary much, but both G height and BSD are determined by inserts in the molds. If the inserts sit a bit higher, BSD will be larger and G height a bit smaller. These cases are marked in light red. They usually don’t cause problems.

Values marked in yellow are fine for use with tubes, but not tubeless.

Values that fall clearly outside the standards are marked in orange. As a tire maker, Rene Herse Cycles cannot recommend running rims that don’t meet the standards to which we and everybody else designs their tires. Rene Herse Cycles can’t offer warranty support for tires mounted on rims that don’t meet these standards. This is especially important when mounting tires tubeless. (Tubes provide a reinforcement of the tire/rim interface, which gives you a little more leeway with rim/tire fit.)

Note: If the values are ≤0.1 mm outside the specs, we didn’t flag them.

It’s the rim maker’s responsibility to ensure compatibility with ETRTO standards

The above measurements are only intended as guidance. We can’t measure all rims on the market, and we also don’t know how much variation there is between individual rims, especially from different production runs. That’s why the ETRTO standards exist: Rim makers have to design their rims to them, so that tire makers have a baseline on which their tires must work.

If rims don’t meet the ETRTO standards, all bets are off. Tire makers can’t design their tires to fit on rims with unknown dimensions. In theory, a rim maker could make non-standard rims and offer specific tires made to fit on those rims. What they should not do is make rims that don’t meet the standards without anybody telling about it. If you have doubts about your rims, ask the manufacturer whether they meet current ETRTO standards.

We are confident that all Rene Herse tires—tubeless or tubed—are safe to use on all rims that meet ETRTO standards, as long as you stay within the ETRTO-approved tire/rim width combinations. We ride these tires ourselves. The last thing we want to worry about when descending a mountain pass at speed is whether our tires will stay on the rims. And neither should you.