The Lightest Parts in the World

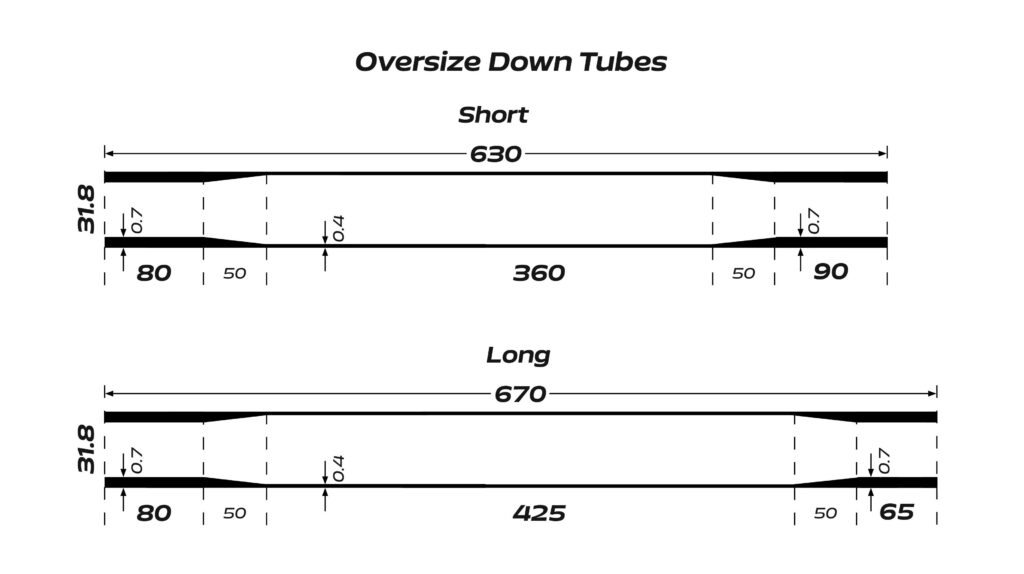

Looking over the most popular articles in the RH Journal this year, our front derailleur made it into the top five! Clearly, this unusual derailleur has caused quite a stir: It’s operated directly via a lever behind the seat tube. Derailleurs don’t get more analog than this!

Readers liked that the Rene Herse front derailleur isn’t just different, but it really works. It has already proven itself in gravel races like Unbound XL and bikepacking FKTs on relentlessly hilly routes that required hundreds of front shifts—a true test for any front derailleur.

What resonated most with our readers was the derailleur’s weight: At 86 g, it’s the lightest front derailleur available today. Once you add shifter and cable (or battery) required to operate other front derailleurs, the Rene Herse derailleur weighs less than half as much as modern systems.

To us, the derailleur’s record-setting weight is not a big deal. There are quite a few Rene Herse parts that are the lightest of their kind. And most of them can be retro-fitted to almost any bike, unlike the front derailleur that requires custom braze-ons.

Our parts may be light, but we never set out to design the ‘lightest’ of anything. We don’t chase numbers. Instead, we leave no stone unturned to develop the best-performing parts, period. That they often turn out to be superlight is just icing on the cake. It’s the result of sound, innovative design, not because we set ourselves a target weight to beat.

Today we’ll look at a few of our ‘lightest-in-the-world’ parts. What makes them so light? How do we make sure they are suitable for the toughest races and adventures—and for many years of everyday use? (Our warranties are the longest in the industry, because we are confident that our parts will last the distance.) We’ll also look at how we could make these parts even lighter, if we were true weight-weenies—and why we’re not going there. And finally, we’ll explain why we care about the weight of our bikes and components.

Lightest Modern Road Tire

If we define a modern road tire as being at least 28 mm wide, then our Elk Pass is the world’s lightest modern road tire. It weighs just 185 g. (Apparently, there are a few 23 and 25 mm tires that are a couple of grams lighter—but even pro racers don’t run tires that narrow any longer.) The Elk Pas measures a full 30 mm on narrow rims, and a bit more on wide rims.

How we made it so light: The light weight of the Elk Pass comes from its Extralight casing, which uses very strong and very fine threads. The smaller diameter—the Elk Pass is a 26″ tire—obviously helps, too.

The Elk Pass is strong enough for some pretty rough roads—Natsuko rides it on gravel without problems. Natsuko is also the main reason we offer this tire: Smaller riders like her are just much happier on bikes with smaller wheels, which eliminate many of the compromises found on small bikes with big wheels. The Elk Pass is also a great choice if you’re looking for a super-fast and super-comfortable 26″ tire in a road-bike width.

OK, I’ll admit that the small wheel size of the Elk Pass is a bit like cheating. So let’s look at 700C tires instead. Rene Herse 700C tires are also lighter than those from mainstream makers. Our 700C x 28 Chinook Pass Extralight weighs just 230 g. Compare that to the Conti GP 5000 S or the Vittoria Corsa Pro Speed: Both tip the scales at 250 g. Our ultra-supple casings make our tires faster and more comfortable—and also lighter.

The difference is even greater for our wide tires. The 700C x 44 mm Snoqualmie Pass is by far the world’s lightest gravel tire in the popular 42-45 mm width range. The Extralight weighs just 335 g and the Endurance comes in at 420 g. Most comparable tires from other makers weigh more than 500 g. And yet the Snoqualmies are strong enough for tough races—above is Lauren de Crescenzo on her way to winning the 2021 SBT GRVL race in Colorado on Extralights. She won again the following year, this time on the Endurance version. The Snoqualmie Endurance has also been ridden to numerous top-10 finishes in the Unbound 200—clearly they are tough enough for the Flint Hills of Kansas.

The Snoqualmies are the fastest gravel tires, both on the steel drum at www.bicyclerollingresistance.com and in our real-road tests. Lightest, fastest, tough enough to win races—there’s much to like about these tires. And in case you don’t run 44 mm tires, it’s good to know that other Rene Herse tires are essentially the same, just in different sizes.

How we could make them even lighter: We intentionally make the tread of our smooth tires a little thicker in the center, where it wears down as you ride. This doubles the miles you’ll get out of your tires, but adds only a few grams of weight. It also doesn’t measurably change the rolling resistance. (We’ve tested this.) The shoulders of a tire don’t wear, so we keep them thin. That’s where the tire flexes, so we want that area to be ultra-supple—and ultra-light.

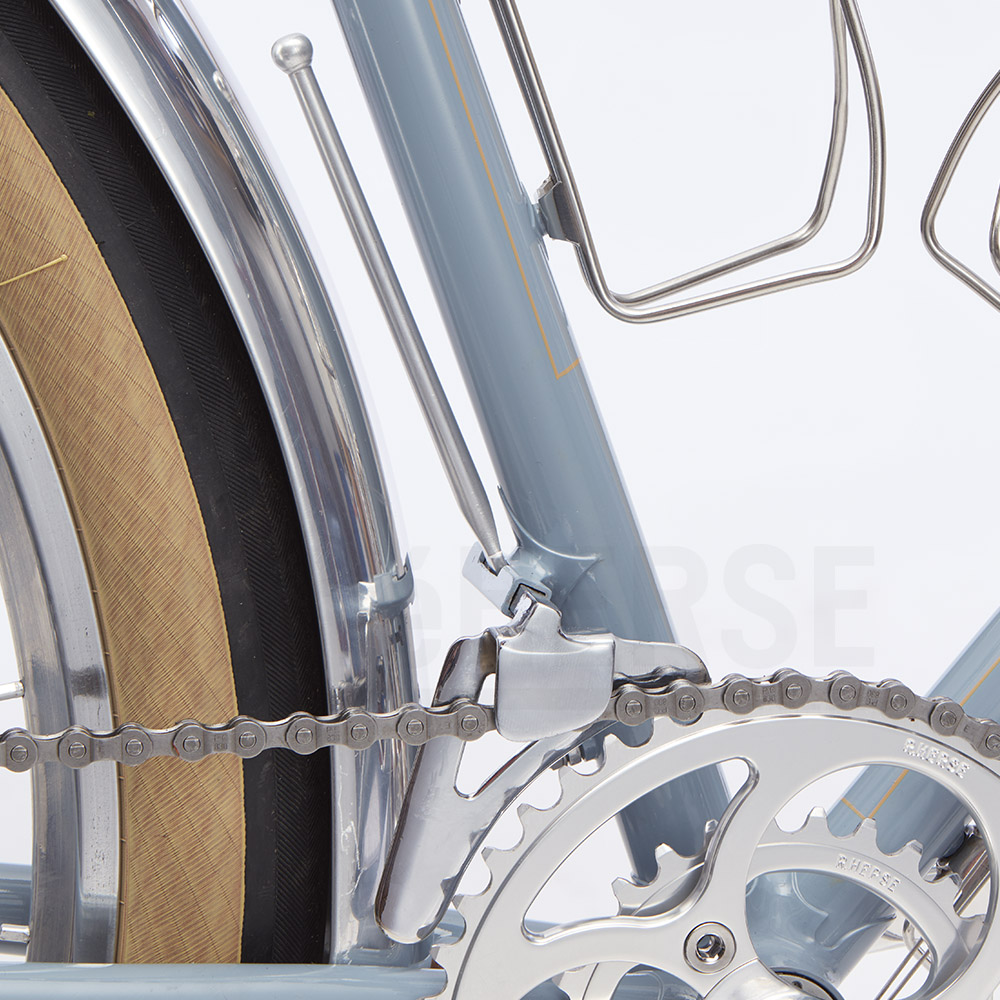

Cantilever Brakes

Rene Herse cantilever brakes weigh just 75 g per wheel (with pad holders, but without pads*). That makes them the world’s lightest canti brakes by a good margin—lighter than carbon cantis. When it comes to sidepull brakes, comparisons are a bit more difficult. Cantis need posts and a straddle cable hanger, but there’s a lot less (heavy) cable housing than with sidepulls. All things considered, our cantis are strong contenders for the title of the world’s lightest brakes. If they don’t hold that ‘record’ outright, they’re within a few grams.

How we made them so light: Our canti brakes are a perfect example of the Rene Herse design philosophy. Where others take existing brakes and replicate their parts in carbon and titanium, our brakes start with a clean sheet of paper. Forged arms are rare among canti brakes, but they are key to light weight. Forging aligns the grain inside the metal. It allows us to make arms that are incredibly slender, yet stronger than other canti brakes. The springs wrap around the arms, rather than go into holes (which would require extra material to surround those holes).

We’ve also eliminated the screws for adjusting the spring tension. Those were needed on OEM brakes, where the stiffness of the right and left springs often varied by quite a bit, and you had to compensate for that. We make our springs to the highest specs, and they all have the same stiffness, so no adjustment is needed.

More weight is saved by a thin straddle cable, which we can use because the ends swivel where they attach to the brake arms. This eliminates stresses and prevents fraying. The thin straddle cable is more than just a weight reduction measure: The cable doesn’t bow when the brake is open, so you get less dead travel when you pull the lever. (With other cantis, the first part of the lever pull straightens the cable, before any brake power is transmitted to the rim.) As a result, the Rene Herse cantis aren’t just the lightest, but also among the most powerful rim brakes. They have excellent linear brake feel, so you can finely modulate them as you brake deep into a corner. That’s how it should be—light weight contributing to excellent performance, not detracting from it.

How we could make them even lighter: We could drill holes in the pad holders, as Peter Weigle did on his bike for the Concours de Machines (above). The savings would be just a few grams, but there’s no harm if you decide to do it yourself.

Musette Bag

Sometimes, making the world’s lightest is simple: Use superlight materials and leave out anything unnecessary. The Rene Herse Musette Bag weighs just 25 g. It’s big enough for three waterbottles or—more relevant for most of us—breakfast for a family of four, if you pass a bakery on the way home from your early-morning ride. If the day heats up unexpectedly, the musette bag can carry tights and long-sleeve jersey, allowing you to enjoy the nice weather without overheating.

How we made it so light: Made from ultra-strong and ultra-light Silnylon, the Rene Herse Musette Bag doesn’t have bells and whistles that would add bulk and weight. In fact, it’s small enough to carry in your underseat bag on every ride—it’s no bigger than a (very small) TPU tube. And if you need extra carrying capacity, you’ll be glad that you’ve brought it along.

How we could make it even lighter: We made a few prototypes from an even lighter material. However, the cost would almost double, and the weight savings were just 3 grams. We want our products to be affordable, and we don’t chase light weight at any cost.

Bikepacking Rack and Bag

Our musette bag isn’t the only ultralight ‘luggage solution’ in our program. We’ve also created the world’s lightest production rack, the CP-1. It weighs just 168 g—and that even includes a light mount.

How we made it so light: Strong Cromoly tubing and smart design are responsible for the light weight. The only drawback: You need a bike with centerpull brakes, since the rack mounts to the pivots with our special double-ended bolts. That’s why we also offer our UD-series racks for bikes with disc or canti brakes. Those racks weigh just a little bit more—they were the lightest racks in bikepacking.com’s big front rack test.

The Concours de Machines handlebar bag is the world’s lightest for its volume: It holds 10.9 liters, yet weighs just 266 g.

How we made it so light: Using the space inside the handlebars allows creating a bag with an excellent volume-to-fabric ratio. Using naturally water-resistant fabric eliminates the need for a (heavy) liner. Lightweight loop closures also save weight, plus they’re easy to operate with one hand.

However, you do need a rack to support this type of handlebar bag. Even if you add one of our racks, this bag-plus-rack system is lighter than other bikepacking bags for the same luggage volume and weight.

Recently, we’ve added some weight to make our handlebar bags completely waterproof—using waxed fabric—and a strap at the bottom to keep the bag securely mounted on rough gravel roads. They are still lighter than other bags, but not as light as the Concours de Machines bags. (We have a few of those left, if you want the world’s lightest handlebar bag for your bike.)

How we could make them even lighter: We could leave off the light mount on the rack, but then you’d need a separate light mount that weighs a lot more. On the bag, the clear pocket at the top adds a few grams, but it’s such a nice place to put your map, route sheet and/or a photo of loved ones to inspire you.

Aluminum Handlebars

Our handlebars are the world’s lightest aluminum handlebars. Our 370 mm Randonneur bars weigh just 262 g. That’s almost carbon bar territory, without the risk of breaking your bars if your bike falls over. (Our aluminum bars may bend, but they won’t shatter.)

Even the more common 400 mm widths of our Randonneur and Professional models are tied for the world’s lightest at 280 g. That’s for the 25.4 mm clamp version—but the 31.8 mm weighs only a few grams more.

How we made them so light (without compromising safety)? High quality is the secret. Our manufacturing process creates no weak spots, allowing us to use thinner material. We then heat-treated the bars to add further strength. All Rene Herse handlebars—each model and each width—are tested for safety. They’ve also proven themselves in gravel races and on bikepacking routes.

How we could make them even lighter: Our bars have a very long reach to give your hands room to roam. Making them shorter would use less material and save weight. That’s besides the point, because we developed these bars for all-day comfort. That they are the world’s lightest aluminum bars is just a coincidence of choosing the best materials and the best supplier.

Frame Tubing

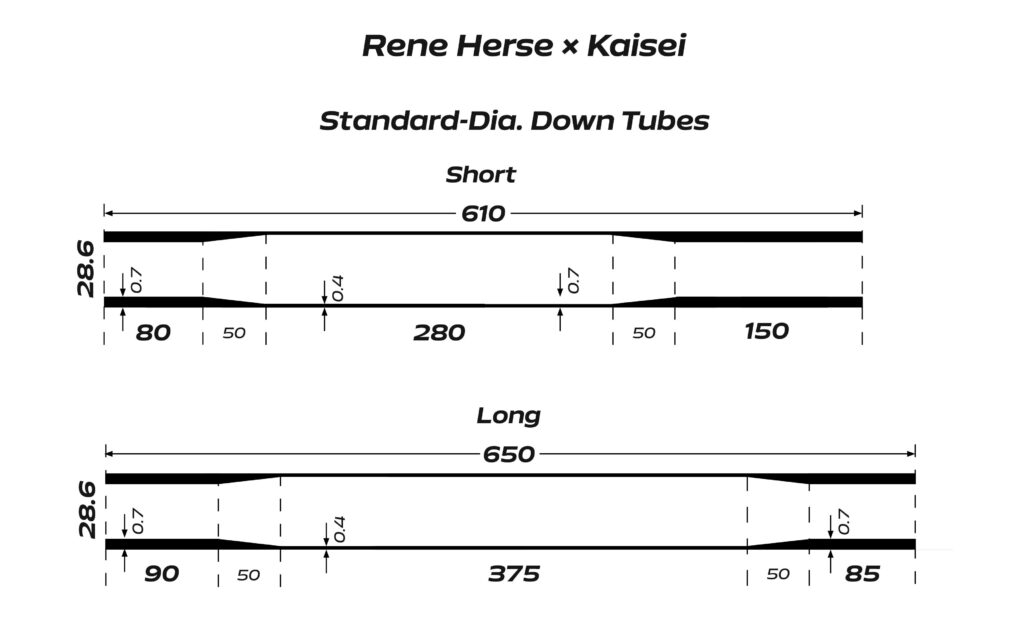

In collaboration with Kaisei, the specialist maker of steel tubing for Japanese Keirin racing bikes, we’ve developed the lightest steel tubing for bicycles.

How we made it so light: We’ve decreased the wall thickness in the center of each tube—often called the ‘belly’—to just 0.4 mm. That’s possible without compromising reliability because Kaisei tubes are of extremely high quality, with uniform walls and no flaws. Japanese Keirin racers depend on their bikes for their livelihood, and if a frame fails, they aren’t allowed to switch bikes until the next racing session. No bike means no income for these racers. For the rest of us, we can trust that our custom frame won’t fail prematurely due to a tubing defect.

Other companies are offering tubes with thin bellies, too, but usually only in a single length. Since the ends of the tubes need to be thicker to allow for welding or brazing, the bellies are only as long as the smallest frames allow. For the average rider, that means that only half the tube has 0.4 mm walls, and the rest is almost twice as thick at 0.7 mm. That’s why we’re offering two lengths, one with a much-longer belly for taller frames.

In fact, there are four versions, because we also offer oversized tubes. If you look carefully, you’ll see that the bellies of the OS tubes are longer, since these tubes are used for taller frames. That way, you get similar ride characteristics over the entire range of frame sizes.

How we could make them even lighter: Well, this one stumped me for a moment. There’s really no way to make these tubes even lighter—except by cutting off a bit at the ends. That’s what your framebuilder will do when they miter the tubes for your frame.

Square-Taper Cranks

Our cranks are another example of how we create lightweight parts. At 495 g for a double with 42/26 rings, they’re lighter than Campy’s top-of-the-line carbon cranks were when they still used square tapers. (Our cranks are also lighter than cranks with integrated bottom bracket spindles, but that’s an apples-to-oranges comparison unless you include the bottom brackets.)

How we made them so light: When we started looking at cranks, we realized that many features exist for the convenience of production, not for performance. Back then, cranks had spiders with five arms. Three arms are all you need, but more arms pull the chainrings into shape even if they aren’t perfectly true. With three arms, the tolerances for the chainrings need to be much tighter. That’s a challenge we gladly accept in return for ultralight weight.

Other makers have (partially) followed suit—most current cranks have gone to four arms. The next step is probably three arms, to make a future ‘new and improved’ version even lighter than the current ones. We’ve never been very good at this ‘iterative’ product improvement. We prefer to make our parts as good as they can be. This future-proofs them, so they’ll stand the test of time.

There’s more to making ultralight cranks than just using three arms: You’ll have to forge your cranks if you want to make them lightweight. CNC-machined cranks don’t have the metal grain aligned, so they need extra material to compensate for this inherent weakness.

Even forged cranks aren’t all the same. Most use the same forging die for all lengths. That’s a convenient production shortcut, but machining the pedal eye cuts through the metal’s grain structure and eliminates most of the advantages of forging the cranks in the first place. That’s why we use dedicated forging dies for each length. And that’s why ours are the only small-production cranks that pass the most stringent EN ‘Racing Bike’ test for fatigue resistance.

How we could make them even lighter: A larger bolt-circle diameter would also help with pulling the chainrings into shape. Then we could make the rings thinner and lighter, since they don’t need to be as stiff. But we’d lose one of the most important features: custom gearing with a wide choice of chainrings between 24 and 52 teeth.

To round off this review, let’s talk about a few Rene Herse parts that are not the lightest in the world. Our TPU tubes could be even lighter, if we pushed the wall thickness to the limit. We chose to make them a little thicker instead. This adds just a few grams, but it greatly increases durability and resistance to punctures and pinch flats. It also makes installation easier.

Our NUDA carbon minipump (top) is also not the lightest in the world. If you want the absulte lightest, we also sell the NANA (bottom). The NUDA is 5 grams heavier, because its barrel is longer. In return, the NUDA pushes out 85% more air per stroke. Whereas the NANA is best reserved for emergencies, I often carry the NUDA as my only pump when traveling. Even inflating a 55 mm tire isn’t a chore, thanks to its light action and fast strokes. And at 30 g, the NUDA is still one of the lightest in the world.

It all adds up

Years ago, Mark and I disassembled a bunch of bikes and weighed each part, to see why some were much lighter than others. The answer is no surprise: Every part matters. The end result of many small savings adds up to several kilograms. That’s how my Oregon Outback Rene Herse (above) weighs just 10.3 kg (22.7 lb)—with 54 mm tires and a comfortable leather saddle. That weight includes lights, rack, pedals, bottle cages, pump and even the shorty ‘aero fender fairings.’ That is lighter than most carbon gravel and bikepacking bikes, once you add the equipment for 24-plus-hour rides.

Why do we care?

Why do we care about light weight, when the rider weighs so much more than the bike? Obviously, if you’re racing or going on spirited rides with friends, losing even just 3 seconds on a long climb will make a difference. Three seconds is actually more than it sounds: In a race, 3 seconds is the gap where you’re considered ‘dropped’ and support cars pass you to follow the main peloton. But many of us don’t race and don’t really care about a few seconds here or there.

When I asked Natsuko about why she likes a light bike, she explained that it allows her to envision routes that otherwise would be too long and too far between resupply stops. She also mentioned that she likes to carry a bit more in her bag: her favorite hair conditioner when staying in inns or a portable coffee maker when camping. Having a light bike allows her to worry less about the weight of her luggage.

For me, it’s mostly about the feel of the bike. In many situations, our bikes move independent of our bodies: when we turn the handlebars, when we rock the bike as we climb out of the saddle… In those situations, we really can feel the weight difference.

In the end, a lightweight bike isn’t just about performance, but also about what Seattle framebuilder Bill Davidson calls “the joyful feel when riding a light bike.” And that’s something we all can get behind, whether we love going fast or don’t really care about speed: We all ride for the joy of cycling!

More Information:

- Click on the images above for more information about each component.

- A steel bike lighter than carbon

- The fastest gravel tires on www.bicyclerollingresistance.com—and why we don’t really care!

* Why do we (and most others) weigh our brakes without pads? The only way to make brake pads lighter is to make them thinner, which just means they just wear out faster. It’s a bit like making the lightest water bottle—if we weigh full water bottles, we’ll just start a race to the smallest water bottle (with the least water inside). To avoid that, brakes are usually weighed without pads.