The Science of Winning the Tour

On Sunday, I was chatting with Ted KIng. The Tour de France had just ended, and Ted compared this year’s Tour with the ones he raced a dozen years ago. “What an exciting race!” exclaimed Ted. “There were so many highlights. Take Stage 20: For Kaden Groves, a guy who is more of a sprinter, to win such a difficult stage—that was exceptional.” He continued: “So much has changed since I raced in the Tour. Speeds are so much higher now because there’s no let-up in the action any longer. It used to be that a break went up the road, and the pack just sort of rode along. Then, at some point, somebody decided to go after the break and try to reel it in. Now the action is non-stop. Just consider the gaps in the g.c.: Second is 4.5 minutes down—that’s huge. And tenth is more than half an hour back.”

Ted continued: “Everything is a lot more scientific now. Back then, there wasn’t that much thought given to aero—at least for the road stages. Of course, the importance of aerodynamics for speed has been known for 100+ years… We were just as low on our bikes back then—see the photo above where I’m pulling the peloton on Stage 2 of the 2014 Tour—but my 44 cm bars would be gargantuan by modern standards. Our jerseys were already much more form-fitting than just 10 years prior, but the two riders behind me have theirs unzipped just a little bit, which is something that you’d never see during a flat stage these days.” Ted continued: “Things were starting to change back then. I rode for Cervelo Test Team for a while, and we were the first to take an integrated system approach to the bike, with bars, stem and frame all working together.”—”You also were the first to move to wider tires,” I recalled. “Yes—25 mm!” Ted confirmed. He concluded: “Today, it’s on another level: The racers are so dialed in and narrow and aero.”

It’s clear that more and more science is brought to professional racing. That’s sometimes overlooked, because the focus is—as it should be—on the human exploits of the racers, not on the bikes they are riding. There’s been some talk about the amazing time trial bikes at this year’s Tour, but few noticed three interesting trends, all related to wheels.

It’s encouraging that these trends are based on science, not marketing. It’s a sign that road bikes are maturing after a period of rapid development. Only a rigorous application of science can unlock further gains. UAE Team Emirates may have the strongest rider in Tadej Pogačar, but they don’t just rely on that. They also use the most scientific approach in the peloton to make sure Tadej can develop his full potential. One example of how committed the team was: Pogačar’s unpainted bike for the mountain stages (below) was said to be a few grams below the UCI’s 6.8 kg minimum weight—until the race number was added!

Narrow rims—with hooks!

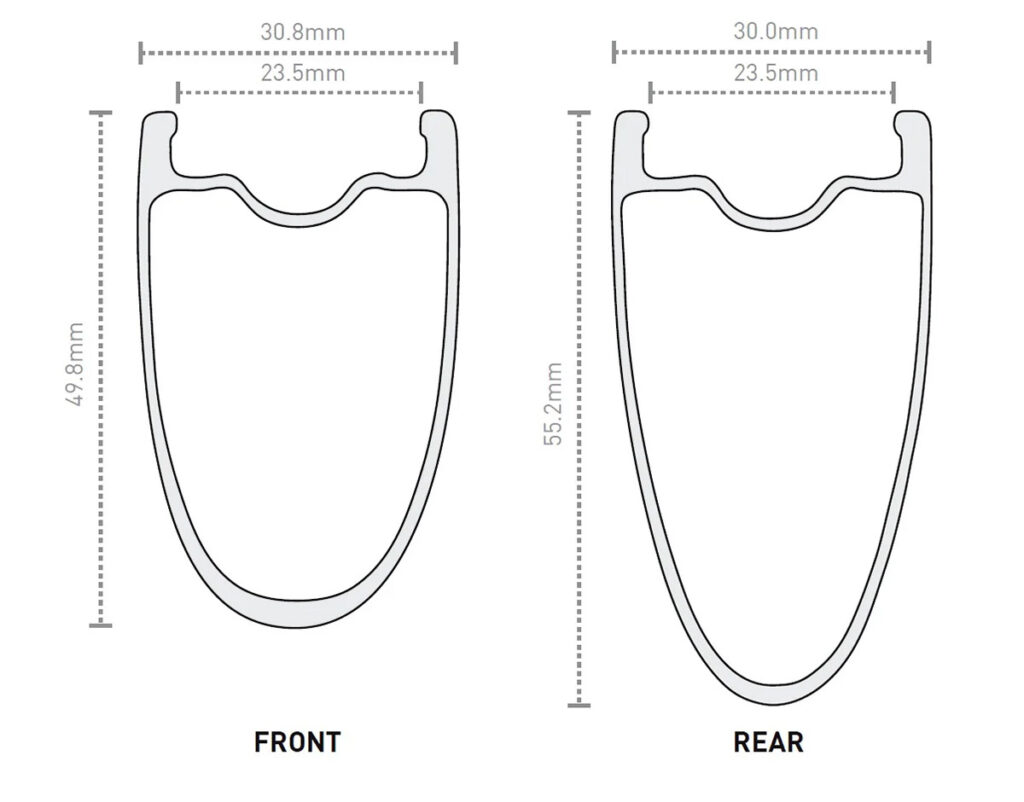

Pogačar’s bike featured a number of components developed specifically for him and the Tour de France. His Enve SES 4.5 Pro rims are ‘just’ 23.5 mm wide internally, down from last year’s 25 mm (internal) rims. Pogačar runs 31 mm tires (actual width), and the rims measure 30.8 mm wide on the outside. What about the much-vaunted ‘Rule of 105’—that the rim should be at least 5% wider than the tire for optimized airflow?

Perhaps Pogačar running wide tires on (relatively) narrow rims is an acknowledgment that the impact of aero wheels has often been overestimated? Back in the day when people measured wheels alone in the wind tunnel, aero wheels were calculated to offer a 2-3% improvement in the aerodynamics of bike-and-rider. But in the real world, wheels are surrounded by other bike parts and spinning legs—they aren’t slicing through calm air. Narrow handlebars and lower positions—which reduce the rider’s frontal area—may be more effective for improving aero.

It’s also possible that Pogačar switched to 28 mm tires for stages where he expected to spend a lot of time alone in the wind. 28s obviously meet the ‘Rule of 105’ with the new rims—and they meet the ETRTO standards (which the UCI now enforces), whereas the old 25 mm-wide rims (internal) could only be run with tires that were 29 mm or wider.

Even bigger news; The new SES 4.5 Pro rims have hooks. Enve was one of the companies who pioneered hookless rims years ago. Back then, at Rene Herse, we analyzed the hooked and hookless rims available at the time. We found that the margin of safety was significantly lower without hooks. However, since then, we’ve worked with the ETRTO (European Tyre and Rim Technical Organization) and the ISO (International Standards Organization) to establish standards for hookless rims. Hookless rims that meet these standards are generally safe to use, at least with quality tires. Enve’s rims have been the gold standard when it comes to tire fit and safety. Why hooks now?

To find out more, I reached out to Jake Pantone, Vice-President of Product and Brand at Enve. We’ve known each other for a long time, ever since Enve and Rene Herse contributed to the above-mentioned ETRTO and ISO standards. Jake explained that the hooks aren’t for tire retention. To make sure a tire stays on a rim, the dimensions of tire and rim are more important than whether there’s a hook or not. (Enve’s testing matches what we’ve found at Rene Herse Cycles.)

Then why hooks? To save weight. How does adding hooks save weight? Well, the hooks aren’t ‘added,’ but the material underneath the hooks is ‘subtracted.’ Here’s the story: A few years ago, Enve made their rim sidewalls thicker to reduce the risk of pinch flats by distributing the force of a rim strike over a larger area. However, that made the sidewall thicker than it needs to be. Removing the material below the outer edge makes the rim a little lighter, while keeping the pinch flat protection the same. Coincidentally, that creates the hook. We’ll discuss the new rims and associated tech in a future post with Jake.

Time trial tires for road stages

With every part of the bike optimized to the nth degree, more and more teams are choosing time-trial-specific tires for road stages. With their thinner tread and extra-supple casings, time-trial tires are lighter and faster. Some observers have warned that these ‘more fragile’ tires increase the risk of punctures and crashes. However, anybody who has watched this year’s Tour didn’t see more punctures than before. Today’s tires are much wider and run at much lower pressures than just a few years ago, and they just don’t puncture as easily. The risk of running ultralight and ultra-supple tires is much lower when you are on 31 mm tires at 60 psi (4 bar), compared to 25s at 100 psi (7 bar) or more.

All these riders running time trial tires—and not having more flats than before—suggests that the tire makers are behind the curve. They still make their ‘road’ tires as strong and stiff as in the past, when there’s no need for that any longer, with today’s wide tires. We probably can expect more wide road tires with ultra-supple and lighter casings in the future. Of course, that’s something we’ve been doing at Rene Herse for a long time. You could say that our Extralight tires are built like time trial tires—yet I’ve been racing them on the rough gravel of Unbound XL and the Arkansas High Country Race with zero issues. (Mine are 54 mm wide and run at 20-22 psi / 1.4-1.5 bar.)

‘The fastest road tire we’ve ever made’

Speaking of ultralight tires, Pogačar’s tire sponsor, Continental, made a tire specially for him and the Tour de France. The new Archetype is available only in a (nominal) 30 mm width—because that’s what Tadej prefers to run. Continental calls it the ‘fastest road tire we’ve ever made.’

What makes it different? According to Continental, the casing is the same as their previous flagship Grand Prix 5000 S TR, but there’s no puncture protection. The tread rubber is thinner and softer, which also makes the tire more grippy.

Some reviewers have complained that there is no data to back up the claims of speed. That’s a curious omission: Continental has a state-of-the-art drum testing lab that is often used in tire tests by German magazines. Surely they’ve run the new tires on their drum. Why don’t they release the data from that testing?

I suspect the answer is simple: The new tires are designed for ultimate performance on the road, not in the lab. The softer tread rubber and more supple construction might actually make them appear slower in drum tests, since those don’t measure suspension losses. Pogačar and his team have already shown that they don’t care about lab tests when they don’t match real-world conditions. That’s why Tadej runs his tires at 55-58 psi (3.8-4.0 bar), even though drum tests suggest that he could save significant watts by maxing out his tire pressure. But those savings aren’t real—they’re just what happens when you measure tire performance in the lab, without a rider on the bike: Vibrations and the associated suspension losses aren’t measured, and that skews the results toward stiffer, harder tires. In the real world, we know that higher pressure doesn’t roll faster—even on the smooth roads of the Tour de France. In that context, it makes sense to develop tires based on what we know works best in the real world, rather than chasing ratings in unrealistic lab tests.

Of course, chasing speed at all costs has real-world drawbacks, too. Testers report that their Archetype tires developed significant wear after just a few hundred kilometers, and the ultra-soft rubber showed nicks and cuts. And then there’s the cost: $ 105 for a relatively narrow tire that doesn’t use much rubber and casing material (compared to a 44 mm gravel tire) shows that top-end materials and small production runs have a price. (Conti also is a large company with significant overhead, unlike smaller companies like Rene Herse that can offer expensive-to-make products at reasonable cost.) Of course, all those drawbacks are a small price to pay when it comes to winning the Tour.

It would be interesting to compare the new tires with a set of well-worn (and thus similarly thin and light) set of Rene Herse Orondo Grade tires. I wouldn’t be surprised if their performance was similar, since both have been designed to perform optimally under the same conditions in the real world (and not the lab).

The future

Will rims get narrower again? Will hookless rims become obsolete, replaced by rims with hooks? Are mainstream wide tires finally going to become as fast and supple as they can be? And will other tire makers finally acknowledge that drum tests are a poor predictor of real-world performance and instead develop their tires for best performance on the road?

Only time will tell, but this year’s Tour de France has offered a tantalizing preview of what the future may bring for tires and rims. It’s nice to see true science applied to bike technology. It’s a confirmation of the old adage that ‘racing improves the breed.’

Further Reading:

Photo credits: Jered Gruber (all photos except 2014 Tour), used with permission