Why we’re ETRTO members

The European Tire and Rim Technical Organization (ETRTO) usually works behind the scenes. If you look at the the sidewalls of a car tire, you see a bunch of numbers like P185/70R14. Those are the ETRTO specs of the tire, and they guarantee that you can buy a tire almost anywhere in the world that will work as a replacement. Even though the ETRTO is traditionally a European organization, because most tire makers were from Europe, their standards have been adopted world-wide.

For example, my ’92 Subaru runs those P185/70R14 tires. The ‘P’ means the tire is for passenger cars. It is 185 mm wide, and 70% as tall as it’s wide. The ‘R’ means it’s a radial tire. And the tire fits on a 14-inch rim. (Car tire standards are a curious mixup of metric and imperial numbers.) There are a few additional numbers that designate load and speed ratings. Those are the numbers you see, but the ETRTO also makes standards for rims and tires to ensure that any tire with the same specs is safe on any matching rim. End users rarely worry about rim/tire compatibility, because the ETRTO standards make this a non-issue.

In recent decades, the ETRTO also got involved in bicycle tires. Before that, there were all kinds of national standards. Most of them were based on the outer diameter of the tire, but only very approximately. British tires were usually measured in inches, and so were old German tires, even Germany has been metric since the 19th century. French tires were metric.

Once bicycles started to be exported, those sizing systems no longer made sense: German 28″ tires were the same as French 700C. British 27″ tires were a bit larger than 700C. Which means that 27″ was bigger than 28″. And 26″ x 1.75″ was not the same size as 26″ x 1 3/4″. The late, great Sheldon Brown catalogued the many different sizes of bicycle tires here.

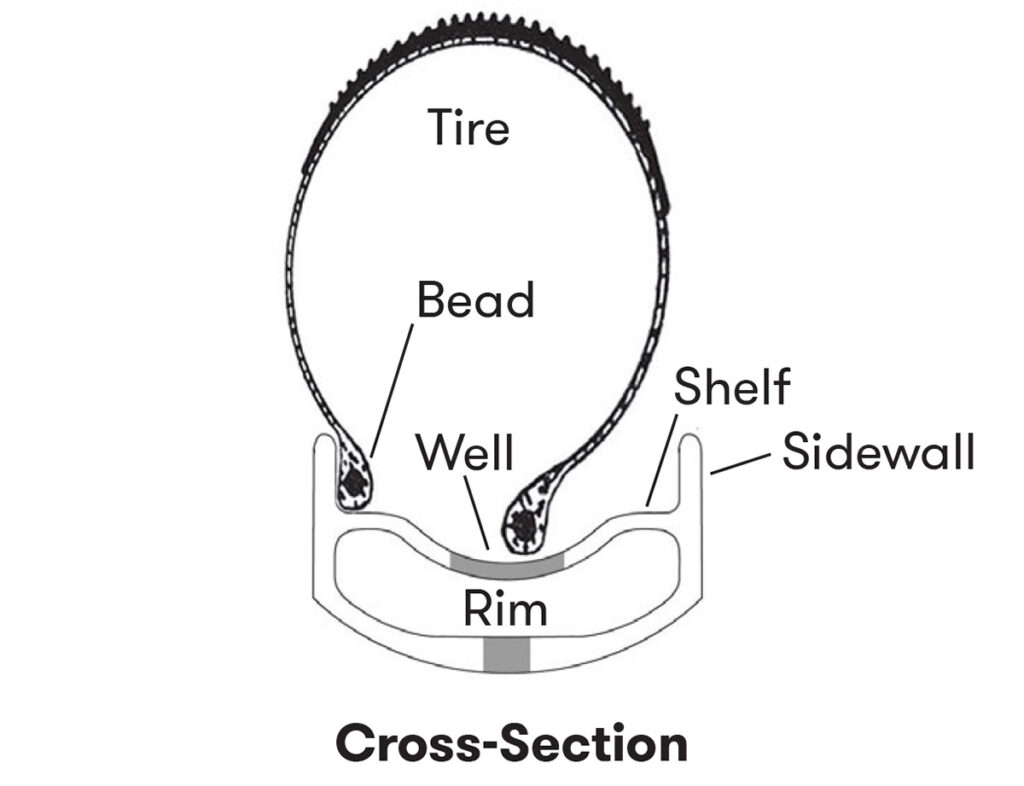

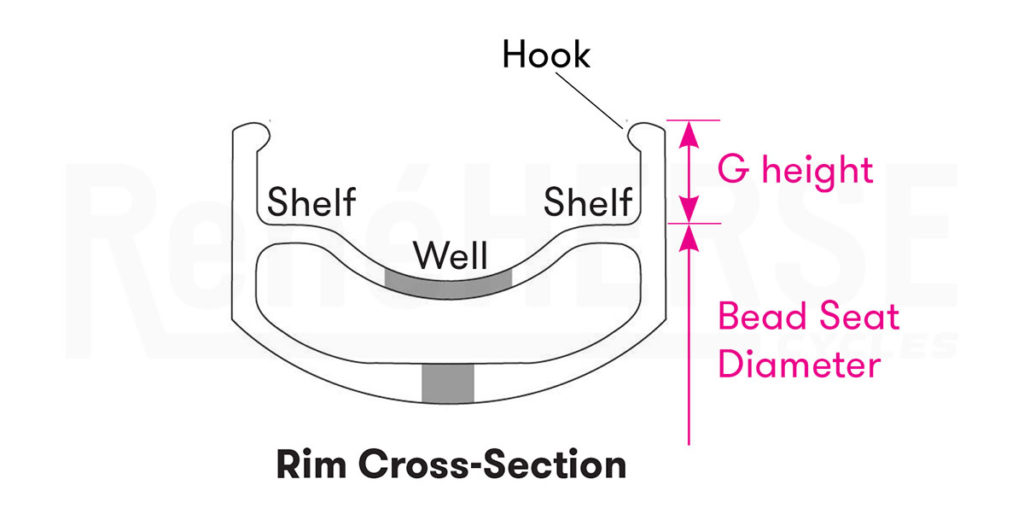

The ETRTO came up with a new sizing system, based on what matters: the interface between rim and tire, and the clearance the tire needs in the frame. Tire sizes are designated by two numbers, for example: 38-622. That’s a 38 mm-wide tire that fits on a rim with a bead-seat diameter of 622 mm.

Since old habits die hard, most of us still call that a 700C x 38 mm tire. And that’s OK—we list both sizes on our tires, like the Barlow Pass above. However, when in doubt whether a tire works on a certain rim, refer to the ETRTO size. Then you’ll discover that 26″ x 1.75″ is a common 44-559 mountain bike tire, whereas 26″ x 1 3/4″ is a 571 mm for old Schwinn ‘Middleweight’ cruiser bikes. Obviously, you can’t mix-and-match those very different sizes.

The most important work of the ETRTO is ensuring the tire and rim compatibility. When tubeless tires first became popular, they would sometimes blow off the rim. All tire brands were affected by this. The reason was that there was no standard yet for tubeless tires and rims. And the old standards didn’t work without the membrane of the tube reinforcing the rim/tire joint. And so the ETRTO started working on standards for tubeless bicycle tires.

That’s where we got involved. When we heard from our friends at ZIPP about the early drafts of the tubeless standards, we realized that they might not work for wide, supple tires. Back then, many companies were starting to make wide gravel tires, but none used ultra-supple casings. Even today, you won’t find a casing like the Extralight on wide tires from other makers. We were concerned that nobody cared about the tires we love to ride, when creating these new standards.

We also felt that our experience with wide tires might be useful to future-proof the new standards—if the wide-tire revolution really took off. (Which it has, as we all know.) So we got involved with the International Standards Organization (ISO). At their U.S. meeting in 2019, I presented a paper about our research on hookless rims and supple tires.

And we became members of the ETRTO. That was more complicated than I had imagined. You can’t just sign up… Your membership application is presented to the annual meeting and voted on by all the other members. Basically, they want only members who are serious and can contribute. It’s also hugely expensive—the annual membership fee is about the price of a good carbon bike. All this really shows that the ETRTO is mostly an organization for and by the huge car tire companies. But they also establish the standards for bicycle tires. Anyhow, we were accepted…

One of the first things we weighed in on was the idea of running relatively narrow tires on wide rims. That’s good for aerodynamics, but it can create problems with tire retention. The initial ETRTO tubeless standards allowed 28 mm tires on 25 mm rims (internal width). Based on input from us and other tire makers, that standard was revised after a short time: Now you need at least 29 mm tires for 25 mm rims.

In addition to providing input, being a member gives us access to all the ETRTO’s standards. Some people complain that the standards are not public, but the ETRTO is financed by membership dues. And end users shouldn’t have to worry about the standards. Just like with my car tires, where I just need to read those numbers off the sidewall, and I can order a new set of tires that’ll fit on my rims.

Fortunately, in the bike world, we’re slowly approaching that ideal. We’ll hopefully be past the point soon where some rims had G heights that were much too low to safely retain tubeless tires. On newly developed rims, we no longer see bead-seat diameters that are too small. That was popular on OEM rims, because a loose fit made it easier to assemble the tires in the big factories. It also allowed greater tolerances. As you can imagine, a rim that’s too large is a huge problem at those factories because the tire won’t go on. A rim that’s slightly too small isn’t a big deal, since most bikes are assembled with tubes and relatively stiff OEM tires. It’s only when the rider wants to switch to tubeless and supple tires later, that they’ll run into trouble. The tighter tolerances mean rims have become more expensive, but that’s a small price to pay for safety.

As we continue to push tire technology beyond what most consider possible, we’ll also ensure that our tires are safe and compatible with all rims that meet current standards. Being a member of the ETRTO is a big commitment. For us, it’s part of ensuring the performance and reliability of our products.