Why not "Made in U.S.A."?

At Compass Bicycles, we think a lot about manufacturing. We know what we want to make, but how should we make it, and where? We are not looking for the lowest cost, but for the highest quality. The conditions under which our products are made are an important consideration as well.

There are a number of small companies who make bicycle components in the U.S., but they are often limited by the technology that is available to them. For example, CNC machines are relatively affordable and small. That is the reason why you see so many CNC-machined cranks and brakes, even though forging would make them lighter and stronger. (CNC machining is a good way to make other parts, like hubs and headsets.) CNC machining also is quite wasteful, as a lot of aluminum is turned into shavings.

In contrast, a forging hammer (photo above) is an investment that only one bicycle company has amortized on their own: Shimano is said to forge their own components. All others, including industry leaders like Campagnolo and SRAM, do not run their own forge.

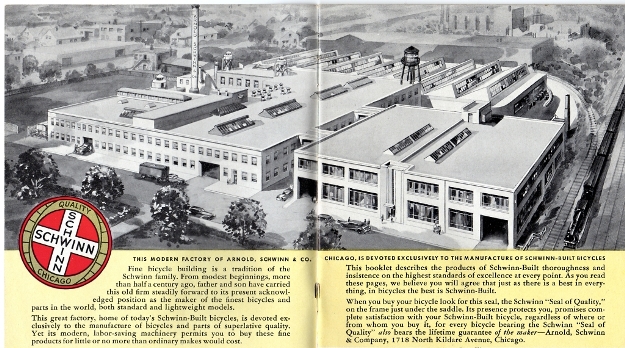

The U.S. bicycle industry never specialized in making high-end components. Schwinn’s famous operation in Chicago was a self-contained factory. Rolls and bars of steel went in on one side, complete bicycles came out on the other side. Yet when Schwinn needed derailleurs or other high-end parts, they imported them from Europe. There simply were no makers of derailleurs and aluminum cranks in the U.S., and even mighty Schwinn wasn’t big enough to make their own. Very few, if any, square-taper crank have ever been forged in the U.S.A. Basically, the technology does not exist here.

Where does the technology exist? Today, the answer usually is Taiwan, which has developed a diverse bicycle industry capable of high quality, along with acceptable work and environmental conditions. Our engineer in Taiwan lives within easy motorcycling distance of the companies involved in our crank project:

- Forge: They forge the crank blanks.

- Machine Shop 1: They machine the chainrings tabs, square tapers and pedal threads of the cranks.

- Machine Shop 2: They make the chainrings.

- Screw Maker: They make our custom crank and chainring bolts.

- Laser Cutting Specialist: They make the pedal washers.

All these companies have experience with bicycle components. Supply paths are short, and oversight is easy. Our engineer can visit the factories while production is under way, which makes it easy to solve small problems that inevitably occur when things are being made. If we made one part in Chicago, another in Texas and a third in Connecticut, this would be very difficult. (The last part of our cranks, the custom boxes, are made in the U.S.)

The Taiwanese are also willing to work with small production runs. When we asked a German screw maker about crank bolts, they told us that the minimum order was 50,000. We would have a lifetime supply of crank bolts!

The photo shows a freshly forged René Herse crank. Taiwanese workers earn good wages and work under decent conditions, comparable to North American workers. Taiwan’s environmental regulations are not as good as they could be, but they appear to be better than most countries outside Europe, Japan, and the U.S.

Many of us would like to see products made closer to home. We would like to support the economies of the places where we live. However, you need an infrastructure to make things.

Paul Krugman explained this in the New York Times: “You need a thousand rubber gaskets? That’s the factory next door. You need a million screws? That factory is a block away. This is familiar territory to students of economic geography: the advantages of industrial clusters — in which producers, specialized suppliers, and workers huddle together to their mutual benefit — have been a running theme since the 19th century.”

Unfortunately, we have been allowing these clusters to disappear all over the U.S. and Europe. In France, there was the cluster of bicycle component makers in Saint-Etienne: Manufrance, Automoto, Stronglight, Maxi-Car and dozens of other companies. Not a single one of them exists any longer!

Another cluster was Levallois-Perret in Paris with its hundreds of machine shops, chrome-platers, casters and other shops. They mostly served the automobile industry (Citroën, Delage, Hispano-Suiza, etc.), but also enabled the small constructeurs of bicycles (and the component maker TA) to do things that would have been difficult elsewhere.

These clusters no longer exist. Ernest Cuska of Cycles Alex Singer once told me how they used to have two chrome-platers within a block of the shop. Now they take their frames, racks and stems to a plater who is almost 100 miles away. TA obtains its forgings from Taiwan. So does Campagnolo. And so do we at Compass.

When you consider that our cranks and brakes are assembled right here in Seattle, perhaps we should label them “Made in the U.S.” (Legally, they are made here from imported parts.) But we aren’t trying to obfuscate, so we say that they are made in Taiwan, since most of the essential parts come from there.

And where possible, we do make products in the U.S. Our taillights, our rack tabs, the leather washers for fender mounting, our alignment tools, and our tire wipers are made by local companies and craftspeople in the U.S. And of course, Bicycle Quarterly is printed right here in Seattle.

Correction: An earlier version of this post stated that to the best of our knowledge, no square taper crank had ever been forged in the U.S. There may have been some cranks made from U.S. forgings in the 1990s (see comments).