Net-Shape Forging and Crank Length

Net-Shape Forging

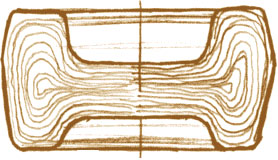

The new René Herse cranks will be offered in one length only, 171 mm, which allows us to have the cranks forged to their final shape. (The photo above shows the raw forging.) The process is called “net-shape forging.” The grain structure of the aluminum is aligned during the forging process, so that it follows the contours of the crank. Net-shape forging optimizes the crank’s strength and enables us to offer a lightweight part without undue concerns about reliability.

Machining Cranks to Length

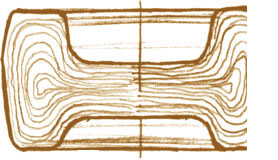

When small-production cranks are offered in different lengths, they usually are made with an adaptable forging, like the raw forging for the TA “Pro 5 vis” cranks shown below.

On the right side, you see how the pedal eye area is elongated. The crank is machined to the correct length by cutting away material near the pedal eye. The following illustrates what happens when you do extensive machining on a forging.

Above is a schematic drawing of a raw forging. You can see how the grain structure conforms to the final shape. This makes for a very strong part.

When we cut off one end, we interrupt the grain structure at that end. Each of these interruptions is a weak spot. On a crank, the interruptions occur at the pedal eye – one of the places that are subject to the most stress. If a crank breaks, it often happens at the pedal eye. Machining the crank to length has eliminated the advantages of the forging process in this area.

“Net-shape” forging keeps the grain of the crank intact. The result is a stronger crank. If you want to offer multiple lengths, a better way is to make separate forging dies for each length. However, this multiplies the cost, especially with small production runs, whereas machining the cranks to length costs very little, because the cranks already are going to be machined for the pedal eye, chainring interfaces and spindle taper anyhow.

The Importance of Crank Length

But what about riders who need a different crank length? I used to think that I was highly sensitive to crank length. I found the 175 mm-long Shimano Deore triple cranks on my touring bike much harder to spin than the 172.5 mm Campagnolo cranks on my racing bike. It was obvious to me that the 2.5 mm extra length made the touring bike’s cranks difficult to spin.

Then I visited my friends Pamela and John in Boston. I had brought my Bike Friday along, but since we were to enter a 300 km brevet together, Pamela suggested that I should ride a bike with better performance. They were to ride their tandem, and John’s bike fit me fine, so why not take it instead? Very well, except it was equipped with 175 mm cranks, and I was concerned about being able to spin such long cranks. John scrounged around and tried to find shorter cranks for me, but his bike was optimized for narrow tread (Q factor), and none of the shorter cranks would fit. I decided to take a chance and ride John’s bike with the long cranks.

To my surprised, I could spin his 175 mm cranks very well. I had a great ride on the hilly roads of Connecticut with my friends, and never felt bogged down like I did on my touring bike. I realized that it had not been the length of the Deore cranks that inhibited my spin, but their width. Their tread (Q factor) was at least 20 mm wider than my Campagnolo cranks. John’s cranks were as long as the Deore cranks, but their tread (Q factor) was almost as narrow as that of my Campagnolo cranks.

Let’s look at the length by itself: The difference of 2.5 mm amounts to only 1.4% of the total crank length. The cranks in the photoshopped image show the range that most manufacturers offer, from 165 mm on the left up to 175 mm on the right. The cranks look similar because they are similar: The longest crank is just 6% longer than the shortest one.

Imagine putting five random people next to each other: Their leg lengths would not be within 6% like the lengths of the cranks in the image. If we wanted to scale our cranks to our leg length, we would need lengths between 140 and 210 mm, as Lennard Zinn suggests. And according to this formula, I would need 186 mm cranks.

TA at least offers their cranks in lengths between 150 and 185 mm, but most cranks are available only in a very narrow range between 165 and 175 mm. People’s inseams and thigh lengths vary by at least 30%, yet most cranks vary in length by less than 10%. There are two possible explanations:

- Crank length does not matter for most riders, and the small differences in the commonly available crank lengths don’t affect how the cranks feel and perform.

- Crank length matters, and the crank makers have it all wrong. They should offer lengths that vary by 30% or more.

My experience suggests that 1. is correct, that small differences in crank length do not make a big difference. Today, I am as happy spinning the 175 mm cranks on Mark’s bike as I am on an old René Herse with 165 mm cranks. Compared to other factors, such as the tread (Q factor) and the flex characteristics of the frame (my touring bike with the Deore cranks also had a stiffer frame that contributed to the “bogged-down” feeling), crank length appears to matter little for most riders.

If you are outside the “normal” size range of cyclists, then you may benefit from significantly longer or shorter cranks. By significant, I mean not just a 165 mm or a 175 mm crank instead of a 170 mm. For example, I went to some lengths to put 150 mm cranks on my children’s bikes, and very tall riders may benefit from significantly longer cranks.

We are confident that our 171 mm cranks will work well for the vast majority of cyclists. For those who “need” a 175 mm or a 165 mm crank, we ask them to re-consider whether the 2-3% shorter or longer René Herse cranks really will feel very different. If future research finds that crank length does matter after all, then all makers will have to start making 140 mm and 210 mm cranks. In that case, we will make additional forging dies for those lengths. Until then, we hope that most riders will be happy with our 171 mm cranks, even if they are 4 mm shorter or 6 mm longer than their preferred length. In our opinion, the advantage of a stronger crank is worth the slight compromise in the length.