Crowdfunding Rene Herse Canti Brakes

Update: The crowdfunding was successful. Thank you! The brakes are now in production. They will be delivered in March 2026.

As a company, we don’t like asking our customers for favors. We hope you’ll buy our products (and read Bicycle Quarterly) because they make your cycling experience better and more fun—and not because you feel the need to support a cause. That doesn’t mean all our products are profitable. In fact, many aren’t—they exist because we need or want them for our own bikes. Rather than create one-offs, we make a small production run that we share with other cyclists and builders.

Sometimes, it’s hard to make a product happen, no matter how much we want it. Many Rene Herse components are forged, because that makes them lighter and stronger than if we CNC-machined them. Forging dies are hugely expensive, and the minimum production runs are very large. That’s not a problem if you are Shimano and make 100,000 crankarms, but it’s a big lift for a small company like Rene Herse Cycles. And there are cases where it’s just not possible without knowing whether there are enough others who want these parts. That’s when crowdfunding is the obvious answer. And so we’re exploring this approach to make products that otherwise just wouldn’t happen.

We’re starting with an existing product: our cantilever brakes. If we want to continue offering them, we need to commit to another forging run—a huge investment. We and many customers love these brakes. However, the reality is that discs are great, too, and they dominate these days. The market for high-end canti brakes is tiny. Before we get to the specifics of the crowdfunding, here’s the story of our canti brakes.

The Rene Herse cantis are a typical example of our product design. The project started when Peter Weigle suggested a collab to create a superlight rando bike for the French Councours de Machines: He’d make the frame and build the bike, we’d provide the components. For a bike where every grams counts, disc brakes were simply too heavy—not just the brakes themselves, but also the beefy fork blades they require. In any case, Peter loves canti brakes. They are elegant and minimalist: just a short arm to provide leverage over the pad, with everything else taken care of by the straddle cable. And, perhaps not coincidentally, René Herse equipped his mid-century bikes with what many consider the best canti brakes—ever. We decided to make an updated version of that amazing brake.

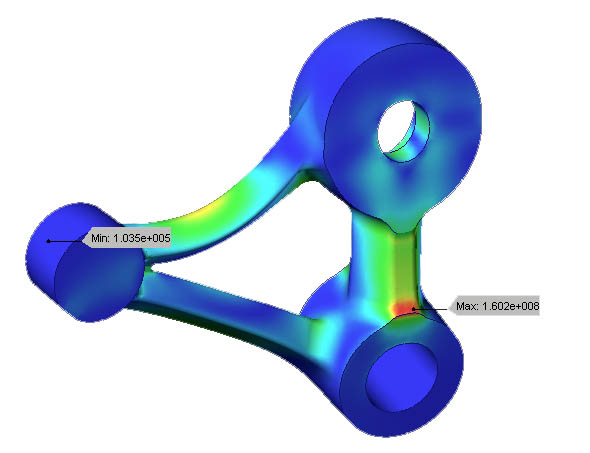

We used Finite Element Analysis to see if the shape could be refined. It turned out that it was perfect—virtually unimprovable. The model above shows the stresses as the brake is applied. (That means both the static stresses from the straddle cable and the dynamic stresses from the rim rotating and dragging the brake pad along.) Everything is blue and green—low-stress. (Ignore the tiny red spot. That’s what experts call an ‘edge error.’ There is no load in that spot.)

It’s remarkable: Even the latest computer technology cannot improve the basic shape of René Herse’s brakes. Maybe we shouldn’t have been surprised—there was a reason Herse was called the ‘Magician of Levallois.’ (Levallois is the suburb of Paris where his shop was located.) Herse had made parts for prototype aircraft before applying the same technology and skill to bicycle components.

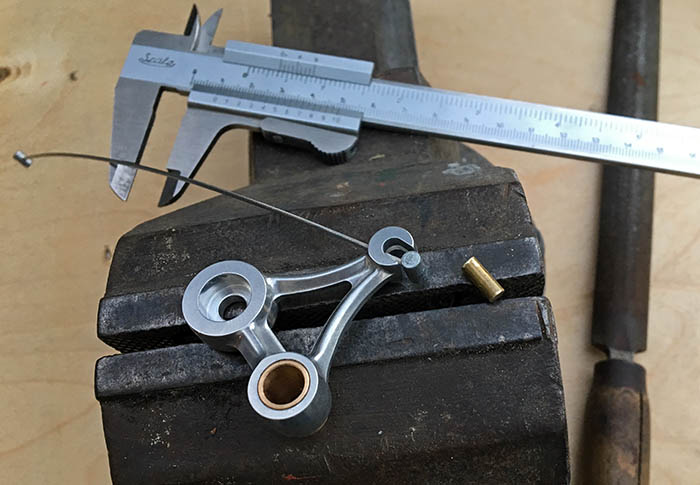

While the basic arm shape was unimprovable, there were a few other things we refined. We use swiveling straddle cable ends to reduce the stresses on the cable. That allows us to use a thinner, more flexible straddle cable. In the photo, you can see how straight the straddle cable runs. Standard straddle cables are thicker and tend to bow—when you first pull the brake lever, you just straighten the cable, without getting any brake power. Without that lost motion, you need less cable pull. That’s why Rene Herse cantis work great with modern road levers—they pull less cable, but have more power. That’s the combo I run on my bikes, and it gives powerful braking with a light touch on the lever.

The brakes also work with classic levers, where they’ll have as much power as other cantis. Since there’s no lost motion, you get more pad clearance to the rim—useful in case your wheel goes out of true.

The ultra-stiff arms further ensure that no brake power is lost to flex, but all goes toward clamping the rim and slowing the bike. Precision machined pivots reduce the risk of judder and/or squeal. We also redesigned the pivots so the new brakes work on standard canti posts. (Back in the day, every brake maker had its own post dimensions…)

As with all our components, performance and durability were the main objectives during R&D. Light weight is not a goal for which we’ll compromise those other, more important characteristics.

When we weighed the new brakes, we were surprised. At 75 g, they are among the lightest bicycle brake in the world—rivaling those crazy all-carbon brakes. Part of the light weight comes from the forged construction, which aligns the grain of the aluminum with the final shape. That’s how the arms are so slender. And as so often, light weight is the result of good design. Our high-quality springs are perfectly equalized, so there’s no need for little set screws that allow adjusting the tension of the springs. The spring itself wraps around the arm, so there’s no need for extra metal to put a hole. We custom-made all the hardware, since standard bolts would have required compromising function and weight. These brakes are jewel-like in their execution, yet they are among the most powerful cantis you’ll find anywhere.

They were the final piece to creating Peter’s amazing bike. Weighing just 9.1 kg (20.0 lb) including fenders, lights, rack, pedals, bottle cages and pump, it was by far the lightest bike that completed the Concours. (One bike was even lighter, but it didn’t make it to the finish.) The Weigle also won the technical classification and was named Choice of the Jury. It finished the event with zero penalties for malfunctions or parts that needed adjustment. This bike is a tour de force, showing what is possible when a skilled and experienced builder like Peter Weigle pulls out all the stops.

The J. P. Weigle for the Concours de Machines is not a show queen. The had to prove their worth over hundreds of miles, both on mountain bike trails and on pavement. This was a real test for the brakes, too. They worked great on muddy trails, and when we descended mountain roads in the rain, scrubbing off speed effortlessly for tight hairpin turns even though the rims were soaking wet. Since then, the Weigle has accompanied me on many memorable adventures in Japan and in the Cascade Mountains. These days, it gets ridden sparingly, since it’s irreplaceable, and I don’t want to wear it out.

Mark and I ran the same brakes in Unbound XL and the Arkansas High Country Race (above). Both races known for their steep and challenging descents. We never felt the need to hold back when descending in the company of other racers on bikes with disc brakes. Every bikepacking FKT I’ve set has been with these brakes. I can honestly say that you won’t find better-performing canti brakes anywhere.

So how does the crowdfunding project work? We need 75 pre-orders by November 30, 2025, to make another forging run happen. Go to the product page and pre-order your brakes. If the project moves forward, you’ll get your brakes in about 3-4 months. Joining the crowdfunding also locks in the old price. Once we get the new production run, the price will go up due to inflation and tariffs. What if we don’t reach our goal? Then you’ll get a full refund by December 15.

Head to the product page to join the crowdfunding and place your pre-order. That’s also where we’ll provide updates on how many orders have been received and how close we are to the goal. Thank you!