MKS: Pedals and more in Japan

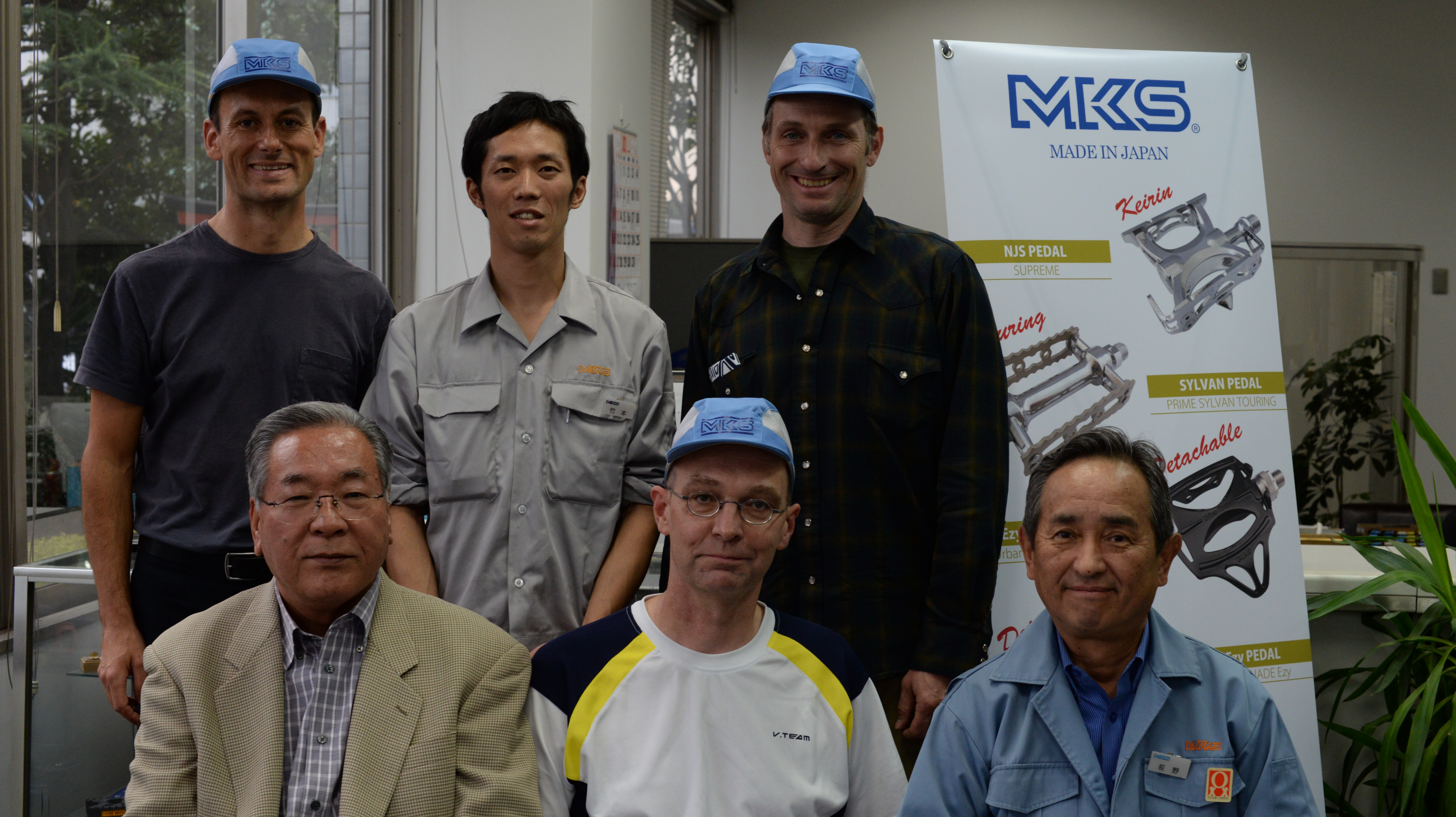

During our recent visit to Japan, we had the privilege of visiting Mikashima Industrial Company, better known as MKS, the makers of bicycle pedals. We had expressed an interest in MKS to our trading company. Fortunately, the MKS’s president, Toshiyuki Ogino (right), had heard about Bicycle Quarterly and was also interested in meeting us.

MKS is remembered by many for making many wonderful pedals for SunTour, but even after that great component maker disappeared, MKS continued to make great pedals.

It was a 1-hour train ride from Tokyo to Sayama-Ga-Oka, where the MKS factory is located. Before we started our tour, we were given MKS caps to show that we were legitimate visitors as we walked around the factory. (Employees all wear company shirts or jackets.)

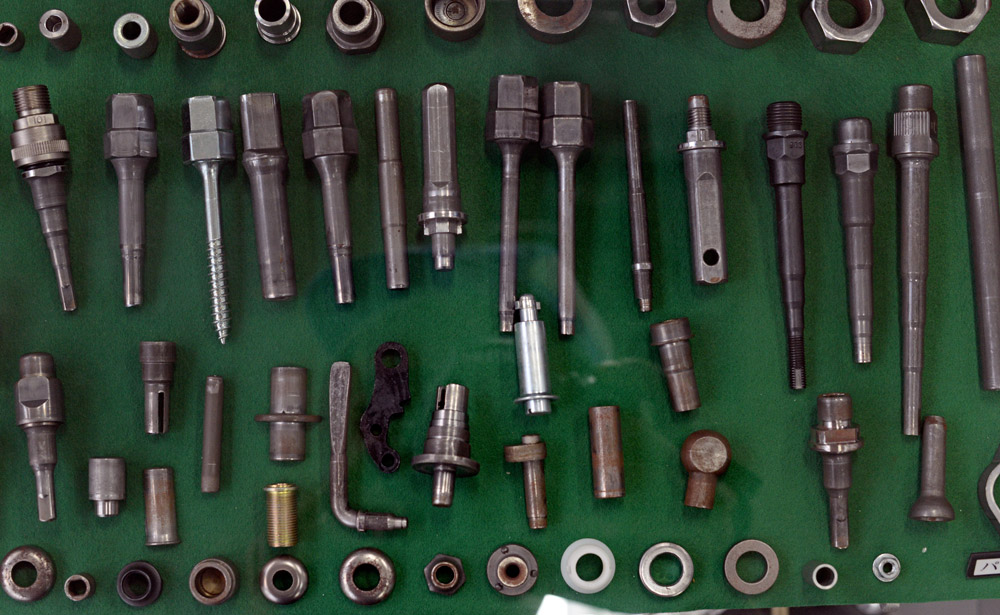

We were surprised by the wide range of products that MKS makes. Bicycle pedals are only half their output. The remainder appears to consist of parts for the automobile industry.

We were asked to not take photos during the visit, which is too bad! It would have been nice to take you on a virtual tour of this impressive factory with its large heat treating ovens, huge presses, forging hammers, polishing machines…

As we enter the first building, one machine is stamping toeclips out of large sheets of steel. It reminds me of making shape cookies with cookie cutters. The toeclip shapes fall into bins, while the left-over steel sheet now has toeclip-shaped holes. It’s fun to watch.

Another machine is forging parts for truck diesel engines. We suspect they are fuel injectors, but it’s too loud in here to ask many questions. And what is “fuel injector” in Japanese, anyhow?

The polishing machines are impressive, with colorful stones rotating in cone-shaped barrels as the parts are polished. The heat treatment ovens are state-of-the-art, as Stefan, our Taiwanese engineer who has joined us for our meetings in Tokyo, confirms. (He used to install these ovens for a living before moving to Taiwan to work in the bike industry.)

The assembly building is much quieter. One room has an assembly line for the aforementioned Subaru headrests. The next room has a single employee assembling the top-of-the-line Keirin pedals. He is wearing white gloves, and next to his workstation are small bins with paper-thin shims. The pedals are equipped with cartridge bearings, but the end play is adjusted with these shims, in 0.03 mm increments. (That is 1/1000 of an inch!) The employee screws in the locknut, checks the play, then removes the nut and installs the next-bigger shim. He repeats the process until the bearing adjustment is perfect. It’s labor-intensive: While we watch, we see only a single pedal being completed and put aside for packing.

We pick up the pedal. Feeling the bearings spin oh-so-smoothly is an object lesson in quality. I want to get a set to keep on my desk and to play with from time to time, to inspire me to insist on the best quality as I am working on our own Compass components.

The pedals have many neat features. The cages are cut away to save weight, yet they support the feet in all the important places. There is a lock for the toe strap, so the old technique of twisting the straps as you feed them through the underside of the pedals isn’t necessary – the straps will stay in place no matter how often you open and close them. Even with a spindle made from strong boron steel, the RX-1 pedals are as light as the classic Campagnolo Super Record pedals with their titanium spindles. And the cages are replaceable, since they’ll wear over time where your cleats touch them.

Of course, these pedals are approved by the NJS for Keirin racing. NJS stands for Nihon Jitensya Shinnkoukai (or Japan Bicycle Promotion Association in English). NJS-approval is an interesting thing: it’s intended to keep the races safe and the playing field level. Every part of the bikes used in these track races must be tested for safety and approved. So for you as a rider, “NJS-approved” means that the pedals are safe even under the strongest riders. (NJS doesn’t say anything about performance or bearing quality.)

The next, much larger room houses the assembly for the less expensive MKS pedals. The contrast to the quiet, unhurried pace of the top-of-the-line pedal assembly is remarkable. The less expensive pedals are assembled by hissing pneumatic tools. The finished pedals drop into buckets with loud clanks. Even here, an employee checks the final bearing adjustment by hand. When we feel a pedal, it’s clear that these pedals will need to “break in” as you ride. The Keirin pedals, on the other hand, have silky-smooth bearings right out of the box.

“Right out of the box” – once you figure out how to open the box! You open the top flap, and then flip open the box like a book. Each pedal has its own little compartment. The smooth lacquered paper stock and tasteful finish ensure that you’ll find a reason to keep this box even after you have installed the pedals.

Keirin racers use toeclips and straps, so MKS also makes what I think are the best toestraps. (And yes, I’ve used Binda Extras and most other famous brands of the past.) Two layers of glove-soft leather sandwich a layer of anti-stretch Nylon. That way, you don’t have to cinch down your toestraps until they cut the circulation in your feet. Adjusting them to a comfortable snugness is enough to prevent your feet from coming out of the clips even when you climb out of the saddle (or sprint in a Keirin race).

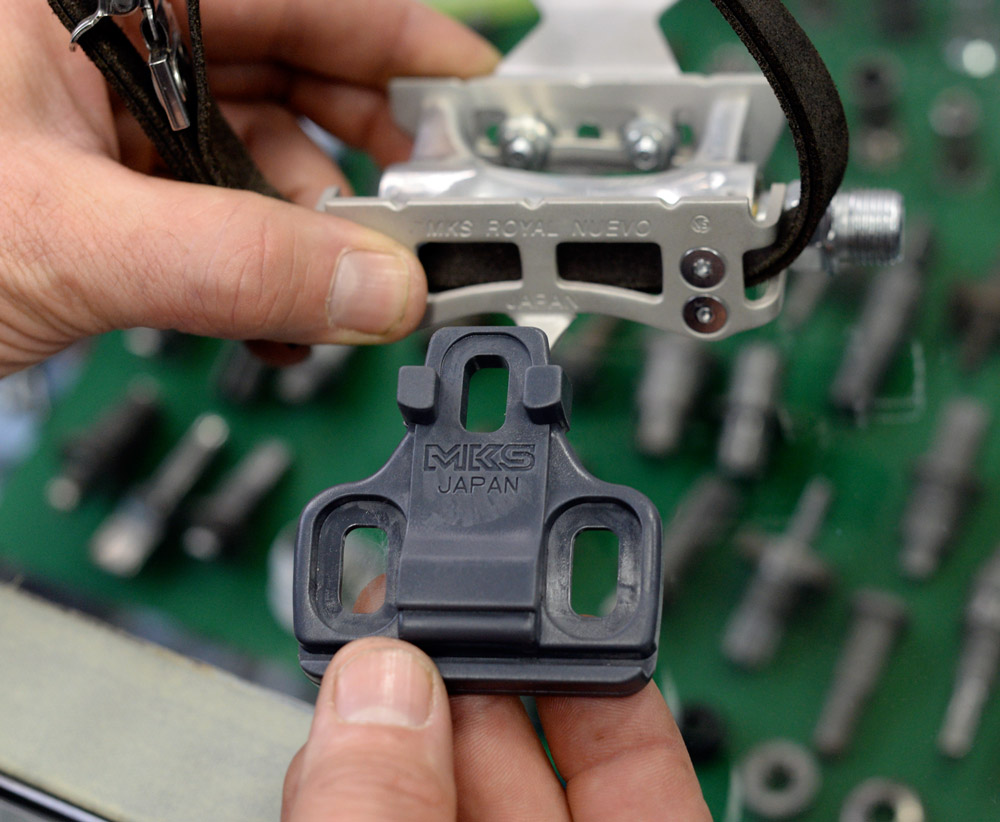

MKS even makes cleats that work with modern 3-bolt LOOK-style shoes, removing one further barrier of entry into the world of toeclips and straps. (They also make more affordable toestraps with just a single layer of high-quality leather, as shown above.)

I am on the fence about toeclips and straps. On the one hand, I love the classic appearance and incredible quality of these MKS components. I have a set of touring bicycle shoes that work with toeclips and allow me to walk. But for all-out efforts, I prefer a more rigid connection to the pedal, which requires cleats that make walking difficult. So for randonneuring, I prefer SPD-style pedals and shoes.

If you have several bikes that you enjoy for their different feel and ride, at least one of them probably should have traditional pedals. I am tempted to put a set of the MKS Keirin pedals on my Alex Singer camping bike.

For riding in street shoes, half-clips are a great option. They locate your feet during the downstroke (which is where you put out all your power anyhow). And on bumpy roads, they prevent your feet from sliding off the pedals. MKS makes these lovely “Cage Clips”, which are welded from steel rod, rather than stamped out of flat steel sheet. Not only are they beautiful, but they also don’t have sharp edges that can scratch your shoes. And they are made from stainless steel, so they won’t rust even if you scratch them up a bit as you start from a stop with the pedals flipped upside down.

After the factory tour, we meet with the engineers and the president of MKS. We decide to import some of the pedals, straps and cages that MKS already makes. And we hope to collaborate on future projects. Wouldn’t it be nice if we had a true randonneuring and cyclotouring pedal designed for long-distance comfort and longevity? The adapted mountain bike components we use today have mud clearance we don’t need, and the down side is a small cleat that puts more pressure on our foot and wears out quicker than is ideal.

In the mean time, click here for more information on the MKS components we sell.