Suspension Losses

Suspension losses often are overlooked, but they are an important factor in tire performance. When we first tested the performance of tires in a roll-down test, we found that very high pressures offer almost no improvements of performance. This contradicted the testing done in laboratory settings on steel drums, so we looked for an explanation. We realized that suspension losses did not occur on the smooth steel drum. The steel drum tests left out one important factor, and therefore underestimated the resistance of the tires.

What are suspension losses? When the rider’s body vibrates, there is friction between the tissues. This friction creates heat, and the energy no longer is available to move the bike forward. Suspension losses were a well-known factor around the turn of the 20th century, when riders still remembered what it was like to ride on airless tires. Not only were they uncomfortable, but also very slow.

How could we prove our hypothesis that suspension losses are an important factor? It’s simple in principle: You need a bike with a power meter, and two surfaces side-by-side: one with smooth pavement, the other really rough. You ride on both surfaces, taking turns during your repeat runs. If the rough surface requires more power, then you have quantified the extra suspension losses on the rough surface. (Everything else, whether aerodynamics, bike weight or temperature, remains the same during these side-by-side tests.)

Finding the two surfaces was the tricky part. At first, we thought of the chipseal overlay that is found in some places around the Olympic Peninsula. There, the road originally was very smooth, but then the main road surface was repaved with rather rough asphalt. The original smooth pavement remains exposed on the shoulder. The problem was that these roads are more than 100 miles from Seattle, and since we needed perfect conditions with no wind, we might have to camp out there for days or weeks until we could do our testing.

After thinking about this for a while, I thought of a very rough surface closer to home: rumble strips (photo below). For those not familiar with them, rumble strips are deep transverse groves cut into the pavement at the edge of the road. When sleepy drivers drift off the road, their cars hit the grooves and vibrate so much that the drivers are supposed to wake up. (The things we do to keep drivers on the road who shouldn’t be there in the first place…)

So we found a flat section of new highway with very smooth pavement, and rumble strips, and went out on a calm day to test. First, we went to some “standard” rumble strips and found that the additional power required to maintain 16 mph was 290 Watt. On the smooth pavement, the rider put out 183 Watt, on the rumble strips, they needed almost three times as much power (473 Watt). In fact, it was almost impossible to keep the bike going at that speed over the rumble strips! This showed that under extreme conditions, suspension losses can be huge.

Then we moved to shallower rumble strips – where we actually could keep the bike going at speed – and measured the suspension losses with different bike setups. We tested tires in different widths and at different pressures. Stiff forks vs. flexible fork blades vs. suspension forks. Padded handlebar tape.

(We tested very early on weekend mornings, and on an off-ramp. That way, there were few cars on the road that could affect the results with their wake. A few times, trucks passed, and we redid the test run.)

We found that wide tires at low pressures were most effective in reducing suspension losses. On the rumble strips, wide tires at lower pressures required only 2/3 the power of narrower tires at higher pressures.

Suspension forks and flexible steel fork blades both had the same effect: They also reduced suspension losses compared to a stiff fork taken from a hybrid bike (shown above). The flexible forks were less effective than wide tires, because they had to deal with the front wheel moving up and down many times per second. Getting rid of vibrations at the source (the road surface) is the best strategy.

Interestingly, the RockShox fork was more comfortable, but no more efficient, than the flexible steel fork of my Alex Singer. Some energy gets lost in the RockShox’s elastomer damping, whereas the undamped Singer fork has next to no internal losses.

Padded handlebar tape did not reduce suspension losses. Once the entire bike is vibrating, the forces are too great to be absorbed even by a thick layer of foam.

Interestingly, the rider’s subjective evaluation of comfort mostly matched the test results (with the exception of the suspension forks). The more comfortable the rider was, the smaller were the suspension losses.

Most surprising part were the results on the smooth pavement: The stiff forks required more power there, too. This seems to indicate that suspension losses are an important factor even on the smoothest pavement. So it seems that putting a RockShox fork on your bike can make you faster even on smooth pavement! You also can use flexible fork blades (the Singer forks were just as fast), and supple tires are even more effective. (Most effective would be a combination of both flexible fork and supple tires.

This photo shows an odd juxtaposition: my classic Alex Singer equipped with a RockShox suspension fork! We used this bike because it has clearance for wide tires and could be equipped with the two forks we wanted to test in addition to the original fork with its flexible blades.

As an interesting side effect, the comparison runs on the smooth pavement once again showed large performance differences between different tires. This confirmed the results of our roll-down tests of tire performance.

We reported the results in the Autumn 2009 Bicycle Quarterly (Vol. 8, No. 1). Keeping with the “rough road” theme, we also looked at the technology of bicycles for the Paris-Roubaix race, and we interviewed mountain bike pioneers Charlie Cunningham and Jacquie Phelan in that edition.

Update 8/15/12:

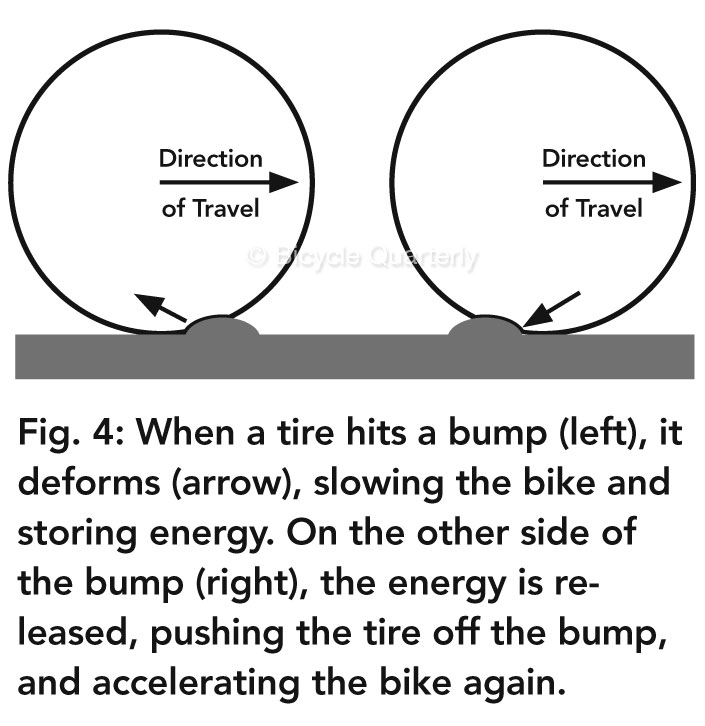

Several readers asked how the energy stored in the tire as it deforms when going over the bump is returned as the bike moves beyond the bump. The drawing below from the Bicycle Quarterly article illustrates the concept:

It’s a bit like a basketball bouncing without losing much height: The kinetic energy of the fall is stored in the ball as it deforms when it hits the ground, then it’s released by pushing the ball upward.