Why slick tires don't stick well

During the R&D of the Compass tires, I was surprised how much difference tire treads can make. I rode three sets of tires with the same casing, same tread rubber and same width, but different tread patterns:

- standard Grand Bois Hetres with large longitudinal ribs throughout the tire tread

- “shaved” Hetres where all tread had been removed to make “slicks”

- prototype Compass Babyshoe Pass tires with our optimized tread pattern

I crashed on the shaved Grand Bois Hetres when the roads got wet. I made the mistake of leaning over as far as I would have on the standard tires, and found that they offered much less traction in the wet.

During my first ride on the Compass Babyshoe Pass tires with their small angled ribs, I almost hit the inside curb. The extra grip of the new tread pattern made the tires corner on a much tighter radius, for the same rider input.

It became clear that slick tires provide relatively poor grip, especially on slippery road surfaces. And large ribs squirm and thus make the bike “run wide”. Why?

How do slick tires work on racing cars and motorbikes? Slick tires for racing cars are so soft that they form a perfect imprint of the road. They interlock with the irregularities of the road surface. This means that they don’t rely only on the coefficient of friction for grip, but also form a mechanical lock on the road surface.

The downside of the soft tires is that they wear out in just a few hundred kilometers. Often, race cars need to change tires several times during a race. And once the road gets wet, slick tires go from phenomenal to almost zero grip. Water forms a very effective lubrication layer between tire and road (“hydroplaning”).

All this isn’t optimal, but car designers have no choice: Their tires use the same surface for cornering and acceleration. Any tread pattern fine enough to interlock with the road would be ripped off the first time the driver steps on the gas. The same applies to racing motorcycles, which put down a lot of power while still leaning over as they exit corners.

In fact, the more powerful racing motorbikes can be “drifted” to safely approach (and exceed) the cornering limits. This would shred any fine tread patterns.

Bicycles are very different. They coast around tight corners. As a result, they use different parts of the tire for cornering and for accelerating. Here is how that translates into an optimized tire tread for road bikes:

Center

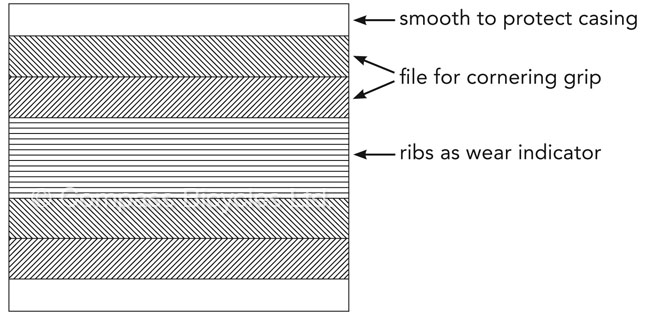

When the bike is going in a straight line, the tread doesn’t matter much. Cyclists don’t have enough power to spin their wheels, and bike tires are too narrow to hydroplane. There is no need to evacuate water from the road/tire interface, and deep groves like those of a car tire serve no purpose.

The center portion of a tire can be slick, but we make ours with fine longitudinal ribs as a wear indicator. Once that tread is worn smooth, you have used up about 30-40% of the tire’s lifespan.

Dots or ribs that are angled or perpendicular to the tire’s rotation might increase the rolling resistance: They have to flex as the tire rotates. Perhaps it doesn’t matter much: The center portion of the tire will eventually wear smooth and become “slick”.

Shoulders

This is where it gets interesting. The tread on the shoulders provides traction when cornering, so it’s of great importance. You spend relatively little time leaning into a turn, so this part of the tire does not wear. The shoulder tread can be designed for optimum traction without compromise. How do we get the same “interlock” as the race car slick tires?

The best solution is to provide little ridges that “catch” on the road surface irregularities and thus interlock with the road surface. One advantage compared to the slick race car tires is that the ridges cut through the water when the road is wet, thus providing the interlock even in the rain. On wet roads, the coefficient of friction between road and tire is reduced by more than 50%, so the interlock between tire tread and road surface becomes much more important.

This idea of interlock between tire tread and road irregularities is nothing new. Michelin’s engineers pointed this out in a paper in the 1980s Bicycle Science Newsletter, and even then, it wasn’t presented as something new or revolutionary.

Since the pavement aggregate is random, you want to provide as many interlocking surfaces, oriented in as many directions, as possible. By making the tread as fine as possible, you have a good chance that a rib lines up with the edge of a piece of aggregate in the pavement. That is why small ribs work best. The ribs need to be strong enough that they don’t squirm during cornering (like knobby tires do). Otherwise, you’d reduce your cornering grip again, and also increase the tire’s rolling resistance. Fortunately, the ribs don’t have to be tall, which reduces how much they can flex.

That is how you arrive at a criss-crossing pattern of fine ribs to provide a maximum of interlocking surfaces. This type of tread pattern was standard on high-performance bicycle tires for so many years, and it appears that there was good reason for this. In the old days, rubber compounds were much less evolved and provided less friction especially in wet conditions. Without the interlocking ribs, the tires would have been very dangerous in the wet. Modern rubber compounds have improved the coefficient of friction, but interlocking still is important for grip, especially in the wet.

Edges

The outermost part of the tire tread never touches the ground. You only need it to protect the tire casing from cuts. This tread can be thin and doesn’t need any pattern.

That is the logic behind the Compass tire tread. It’s not complicated, but it seems to be the only way to optimize a bike’s tire tread. We aren’t the only ones to use this type of thread. It used to be common on most high-end performance tires, and today, a number of companies still use it.

Let’s look at the alternatives:

- Slick and coarse tire treads give up many opportunities for interlocking, and thus will offer relatively poor grip, especially in the wet.

- “Negative” treads, that just cut grooves into the tire, apparently are inspired by car tires, where they help prevent hydroplaning. But even very wide bicycle tires are too narrow for hydroplaning (and our speeds are too low, too). Perhaps a fatbike with slick tires at 50 mph could hydroplane…

- Knobs will squirm in corners and thus make cornering unpredictable and dangerous. (Knobs are useful for traction in mud and snow, though.)

Back to the title: Slick tires are based on a simplified, incomplete understanding of tire grip. They offer less traction in dry and, especially, wet conditions.

Better tire treads exist. It’s important, because the tread pattern makes a very significant difference in how well a tire grips and performs. Being able to lean into a corner with confidence makes cycling both safer and more fun.

Click here for more information about Compass tires.