Rethinking Packaging

Since we’ve started making bike parts again in 2011, we’ve been working on reducing our environmental impact. We were among the first to use custom-designed cardboard boxes with inserts that hold our cranks securely. That has been part of our commitment to reduce our impact – while making sure that our parts reach our customers all over the world in perfect condition.

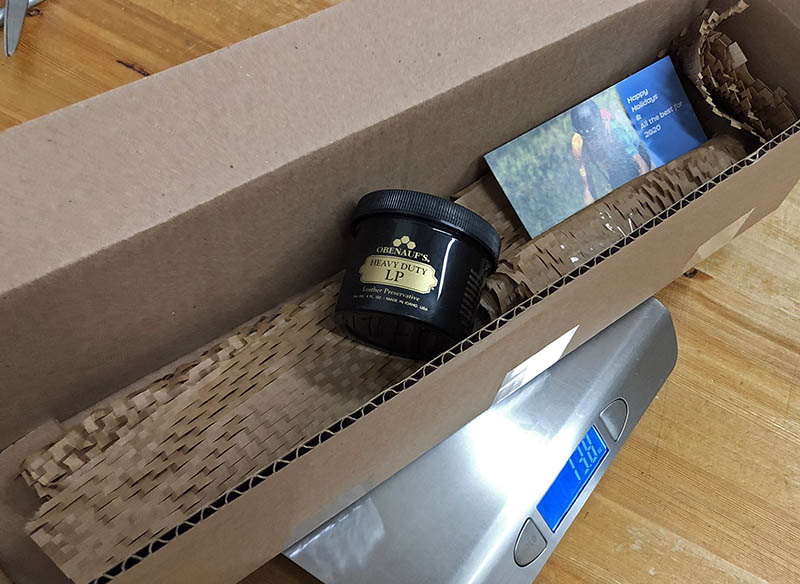

Recently, we’ve moved from plastic bubble wrap to an alternative made from recycled paper. We don’t just use environmentally conscious materials; we use less of them, too. We stock boxes in many sizes to make our shipping more efficient. This doesn’t just use less material, but also less fuel during shipping (and saves our customers money). We source our boxes locally, rather than from the biggest supplier, Uline, which uses its profits to support an anti-environmental agenda.

We also reuse all kinds of boxes and packing materials. Don’t be surprised if your order comes wrapped in Japanese newspapers or in a box that originally held the dishes we use in our company kitchen.

Some customers wonder why we package our tires in plastic bags. The reason is simple: The bag protects the tire from damaging UV light and from drying out. Not all of you immediately use your tires, and it’s good to know that you can keep Rene Herse tires almost forever, as long as they stay in their bags.

The bags also protect the tires during shipping and handling. New rubber is sticky, and if a bare tire falls on the floor, the dirt sticks and can’t be removed easily. Some tire makers now ship their tires without bags, but the distributors usually put them in plastic bags anyway. The dealers remove the bags before putting the tires on display… That looks eco, but it doesn’t reduce plastic waste.

The packaging used during the intermediate steps of production is a big concern for us, even though it’s invisible to customers. Most of our products are made in Japan. Despite a reputation for excess packaging (Japanese cookies are individually wrapped inside the box), Japanese factories are among the most ‘eco’ in the world. At our suppliers, you won’t see half-finished products wrapped in plastic while they await the next production step. Japanese factories are clean and products are handled with care, so the intermediate packaging isn’t needed. Thanks to the high quality and skilled labor, there are also very few rejects that go into waste bins – which also reduces the (invisible) environmental impact.

When we receive shipments from Japan, they are always lovingly packaged – with recycled and re-used materials. A recent box came with empty rolls of packaging tape on top to fill the extra space, followed by a layer of newspaper.

Underneath were the products, so neatly packed that they didn’t need extra wrapping. (The short tubes are for a still top-secret future project.)

Many finished products, like our decaleurs (above), are wrapped in old newspapers. Plastic bags are used where necessary to protect the parts from getting scratched: It makes no sense to risk ruining a beautifully made part to save a few grams of plastic.

Bicycle Quarterly also is shipped in a plastic wrapper. We’ve tried sending out the magazines without, but hundreds of them were damaged in the mail. When it rains, postal carriers walk for blocks holding the mail without protection. Sorting machines wreak havoc as well. Printing and shipping so many extra magazines was not only costly, it also had a greater environmental impact than those four plastic wrappers a year.

All our packaging also balances the need for protection with our desire to reduce our environmental impact. When we published our Rene Herse book, we made custom foam corners to protect the books during shipping. The foam triangles are cut-offs left over from industrial foam production, so we’re keeping them out of the waste stream. And the corners work so well that we’ve had not a single damaged book, despite having shipped more than 1,500 copies all over the world.

We continue to look for ways to reduce our footprint, even if it costs more. (Custom-made cardboard boxes and foam corners don’t come cheap.) I’d love to package our tires and magazines in bags made from cornstarch that can be composted. We’ll keep pushing in that direction. It’s all part of our commitment to reduce our impact, so that future generations can continue to enjoy riding in this wonderful world.

Photo credit: Sic Transit Cycles (Photo 3).