Spring BQ Press Check

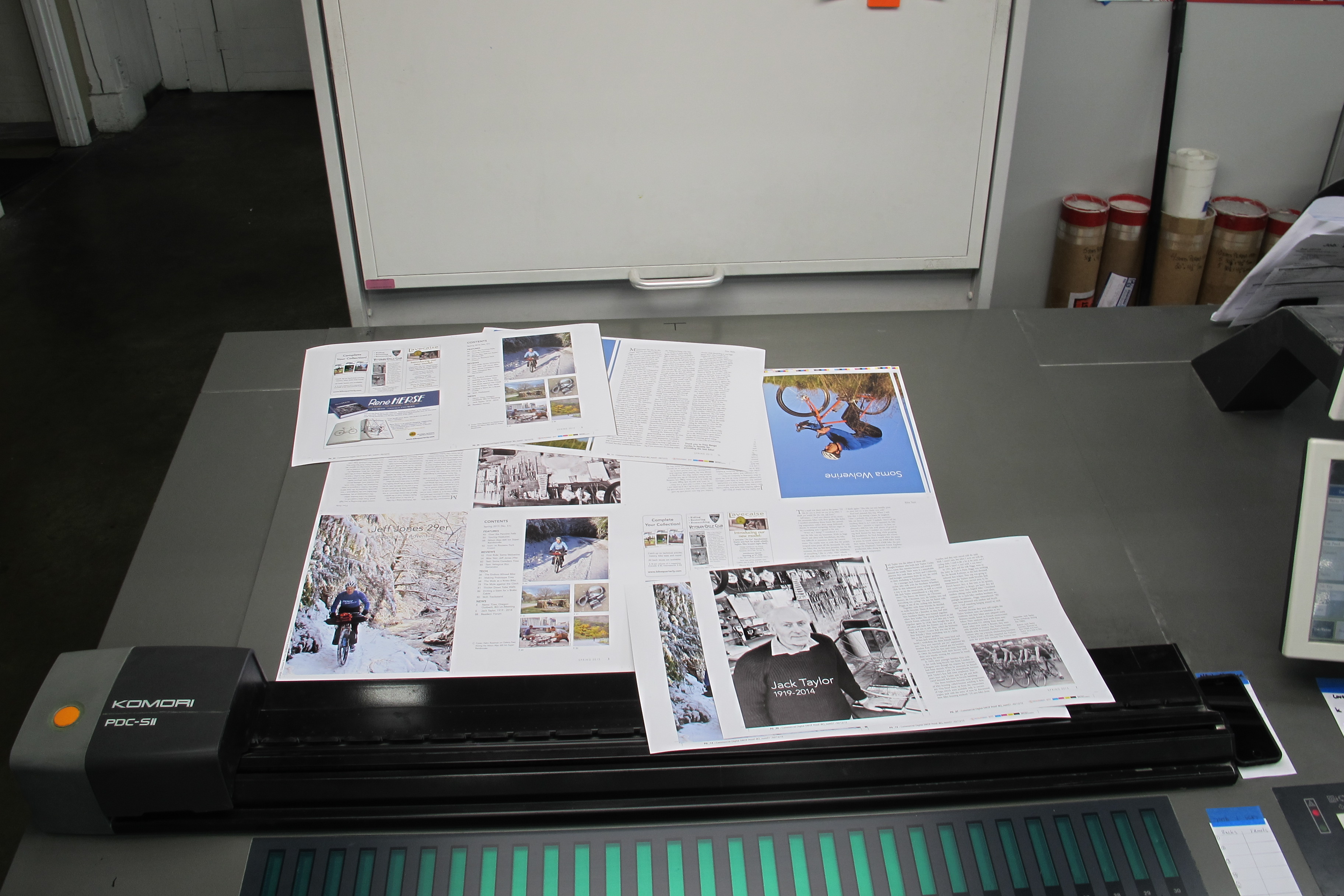

“Stop the Presses!” is a term you really only understand once you have seen these gigantic machines churn out sheet after sheet in rapid succession. They do seem almost unstoppable. Yet here they fell silent again, after just a few sheets had been printed. It was time for the press check. We were at our printer, meeting with the press manager to make sure the printed sheets match the vibrancy of our proofs. This is where our vision for Bicycle Quarterly becomes reality.

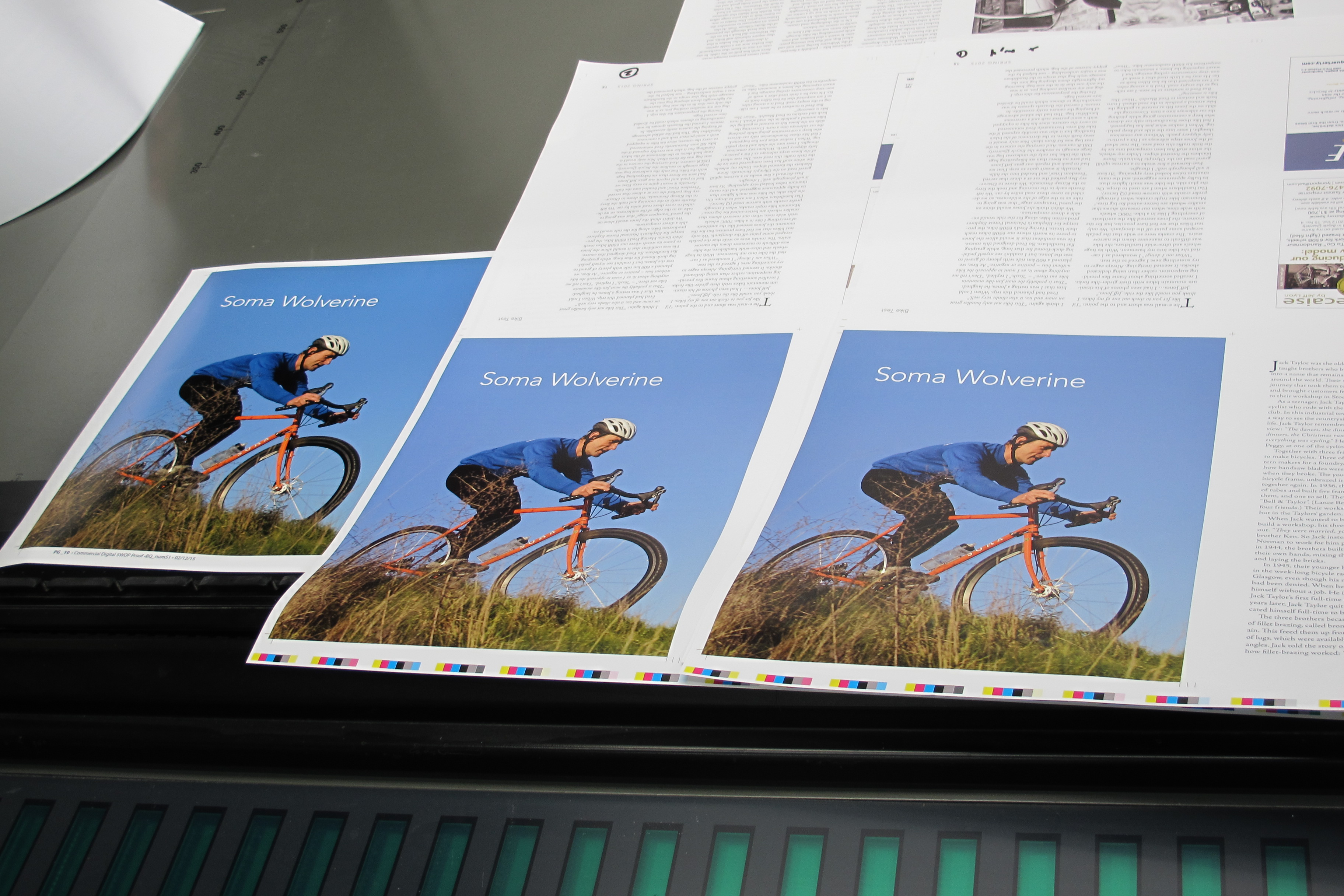

The press manager pulls a few sheets off the press. We compare those sheets to the proofs and tell the manager what we envision. The scanner (shown above) determines the amount of pigment actually put down by the press. The press manager adjusts the color balances and intensities to obtain the most vibrant, life-like image quality. Then the gigantic press starts up again and spits out a few pages with the new settings.

As I see the photos come off the press, I think back to when we were out riding and scouting for photo locations. Back then, I was trying to envision how the shot would look on the printed page. And now that printed page is coming off the press! It’s been a long process to get to this final, vital step in making it all come together.

This time, it seemed to us that the printed sheets looked even better than before. When asked, the press manager told us they started using a new ink with a higher pigment load, which allowed them to push their press settings a little further. He was visibly proud of this change. Once you’ll hold the Spring issue in your hands, I think you’ll agree with him – the new issue looks even better than the previous ones.