Specs of the Unbound XL Rene Herse

After we published the story about a steel bike for Unbound XL lighter than most carbon bikes that line up for this gravel ultra race, a number of you asked about detailed specs of the bike. That makes a lot of sense: Almost everything (except the bottom bracket and two bolts) is available off the shelf. A good builder could make you a similar bike, adapted to your preferences and riding style.

Despite its ultralight weight, there isn’t anything crazy or fragile on this bike. We probably could have dropped the weight below 10 kg, but I didn’t want to take any risks of failure, or compromise performance in any way. To place well in Unbound XL or to set an FKT on a bikepacking route, the bike has to finish first!

There are no aluminum bottle cage bolts that work fine for a while, but may eventually strip or suddenly snap off after many thousands of miles on rough roads. I also didn’t drill holes that weaken parts and save only marginal weight. All the parts on this bike were taken off the shelf and bolted onto the bike, unmodified. Rene Herse components are as light as we can reasonably go—we’ve already removed all the material that is safe to remove.

Weight is only one factor of performance. That’s why I’m running aero fender fairings. Our wind tunnel tests have shown that they reduce wind resistance by 1-2%—and they work with wide tires, unlike aero wheels. That’s worth the 100 g or so that they add to the bike’s weight (including attachment bolts and nuts).

As to the weight, 10.5 kg (23.1 lb) doesn’t sound all that light—until you remember that today’s bikes are weighed without pedals, bottle cages, and often even without handlebar tape. Once you add those, plus lights, bags and all the equipment needed for riding 24+ hours non-stop, an 8-kg gravel racer easily balloons to 11 kg or more. The 10.5 kg weight of my bike includes everything you see in the photos and the handlebar bag.

In last week’s post, I didn’t mention one important part of the bike: wheel size. The photo above shows how tight the space is when you’re running 54 mm-wide tires, beefy chainstays, fenders, and road cranks with an ultra-low Q factor (to facilitate my spin).

The 26″ wheels contribute to the light weight. Obviously, smaller wheels result in lighter tires, rims and spokes. Frame and fork are also lighter—thanks to shorter chainstays and fork blades. The short chainstays also stiffen the rear triangle, so lighter tubing can be used without compromising performance. Another plus of the narrow cranks is a perfect chainline: The front chainring lines up exactly with the middle of the rear cassette, which makes for better shifting on the larger cogs. That’s why I consider the small wheels a win-win situation.

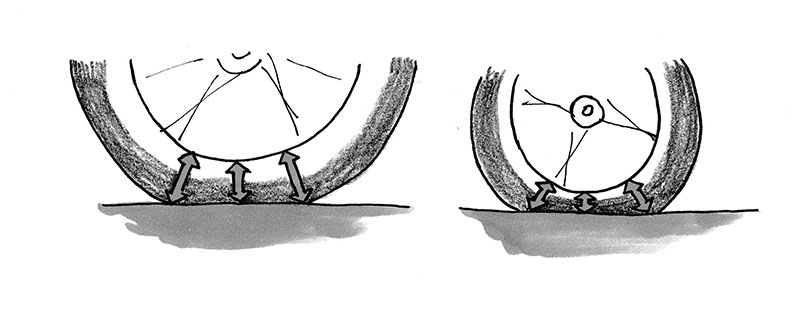

What about the common belief that larger wheels roll over obstacles better? That’s only true for solid wheels. Pneumatic tires are flat at the bottom (above): They absorb irregularities rather than lifting the bike over them. That’s why pneumatic tires are so much faster than solid wheels… and why wide, supple tires are key to rough-road performance—and not big wheels. That’s not just theory—we’ve tested it many times and found that even on very rough surfaces, 26″, 650B and 700C wheels all roll at the same speed. (More on this in the links at the end of this article.)

So that’s the concept behind the Unbound XL Rene Herse. Below are the detailed specs as I ran the bike in this year’s race. (The photos show the bike for Unbound XL in 2022, with Endurance casings, a standard decaleur, a 40-tooth chainring, and quick releases ‘borrowed’ from Peter Weigle’s bike for the Concours de Machines.)

Frame:

- Tubeset: Rene Herse × Kaisei Superlight, long tubes, 0.7 mm curved chainstays

- Dropouts: Rene Herse

- BB shell: Rene Herse custom for pressed-in bearings (prototype)

- Lugs: Rene Herse custom, hand-made by Mark Nobilette

- Cable stops: Rene Herse (ultra-light)

- Cantilever pivots: Rene Herse (high precision for optimum braking)

- Headset: Rene Herse Ultimate (Rinko-compatible)

Fork:

- Blades: Rene Herse × Kaisei ROUND (to resist twist from canti brakes)

- Crown: custom-fabricated by Mark Nobilette

- Dropouts: Rene Herse SL

- Rene Herse stem tube, 1.8 mm

Drivetrain:

- Cranks: Rene Herse One-By 36-teeth

- Crank Bolts: Rene Herse Titanium

- Bottom bracket: Rene Herse with pressed-in bearings (prototype)

- Derailleur: SRAM Red XPLR

- Cassette: SRAM Red XPLR 10-44

- Chain: SRAM Force 12-speed

- The triangular wire on the chainstay keeps the chain from hitting when coasting downhill on rough terrain.

Brakes:

- Rene Herse cantilever, titanium bolts, direct mount pads

- Extra-long straddle cable (front)

- Rene Herse Rack Bolts to attach brake and rack to canti pivots (front)

- Custom-machined aluminum brake bolts (rear)

Wheels:

- Front hub: SON Delux Wide-Body SL, 28 holes

- Rear hub: Hope RS4, 32 holes

- Rims: Velocity A23

- Spokes: Sapim Laser (2.0-1.5 mm), aluminum nipples

- Tires: Rene Herse Rat Trap Pass 26″ x 2.3″ Extralight

- Tubes: Rene Herse TPU

- Quick Releases: Tune carbon/titanium

Contact Points:

- Handlebars: Rene Herse Randonneur Superlight, 40 cm

- Bar tape: Maware pigskin

- Stem: Rene Herse clamp-on, 100 mm, titanium bolts

- Levers: SRAM Red eTap AXS (for rim brakes)

- Saddle: Berthoud Galibier

- Seatpost: Nitto S-65, shortened

- Pedals: Shimano XTR M-9100, short spindle (52 mm)

Lighting:

- Headlight: SON Edelux II, hanging, without switch

- Taillight: Rene Herse (with built-in reflector)

- Light switch: Rene Herse (doubles as stem cap)

- Rene Herse Headset Slip Ring (transmits current from fork to frame without external wires)

Luggage, etc.

- Front Rack: custom-built from steel tubing with Rene Herse rack tabs; Rene Herse rack bolts

- Bottle cages: Nitto 80 (2x); Nitto T; Rene Herse M5 titanium bolts

- Pump: Zefal Solibloc (superlight; out of production)

- Decaleur: Rene Herse Gravel Decaleur (prototype)

- Bag: Rene Herse Ultralight, Size L, with Rene Herse Handlebar Bag Stabilizer

- Aero fender fairings: Rene Herse Smooth Fenders 650B for 38-44 mm tires (H80 650B Std) (shortened)

Bottom Bracket, Gravel Decaleur, Brake Bolts?

If you’re still with me, you’re probably wondering about some of the more esoteric parts oin this list.

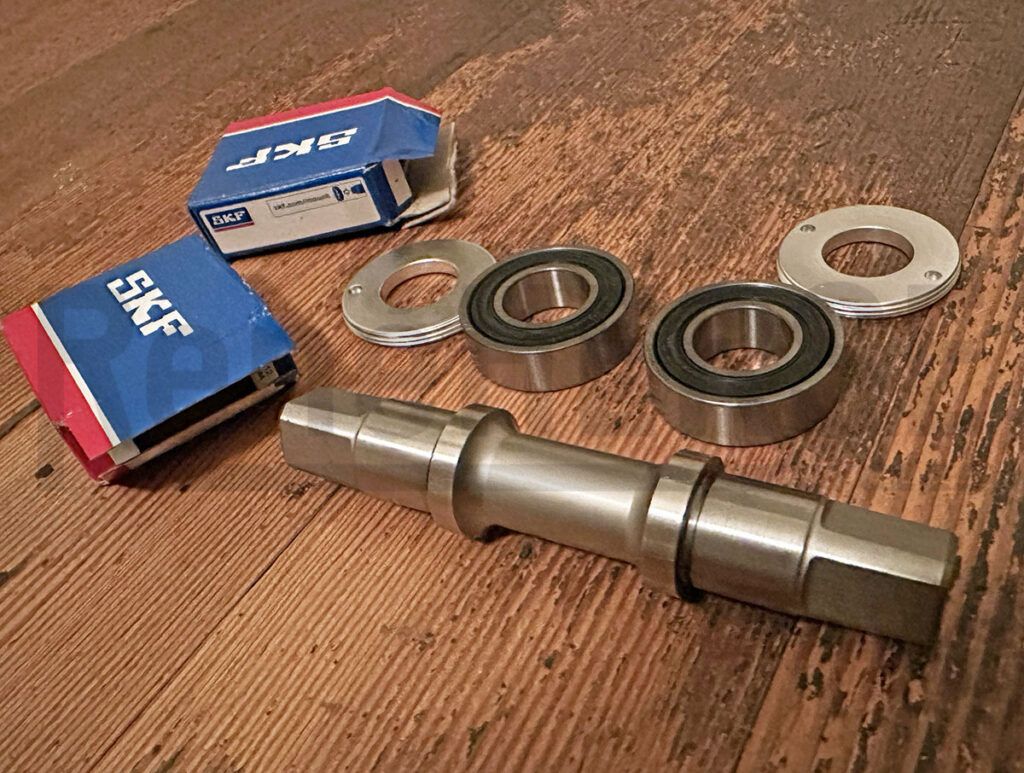

René Herse designed his own bottom brackets. With massive bearings that were pressed directly into the frame, they were lighter than the cup-and-cone BBs of the time, and they lasted for decades without overhaul. In fact, most mid-century Rene Herse bikes still run their original bearings. And if the bearings ever wear out, they are easy to replace. The bearings themselves (Type 6003) are so common that every bearing shop has them in stock. Such durability, maintenance-free performance, and future-proof-ness has timeless appeal, so we’ve made a small run of these BBs—for our own bikes and the 80th Anniversary René Herse bikes.

We’re hoping to make these available to framebuilders in the future, so that more riders can enjoy them on their custom bikes. (They require a special BB shell, so they won’t work as a retrofit.)

The rear brake bolts only keep the brake on the posts—they don’t see big loads. (Unless you are going backwards and brake hard.) You need something to keep the brakes on the posts—otherwise vibrations move them until the springs no longer engage in the holes on the frame—but aluminum bolts are more than adequate.

Realizing this, I machined a small batch of aluminum brake bolts for my own bikes. The savings are minor (10 g), and we can’t offer them for sale. Why not? Imagine what would happen if somebody put them on the front brake, where the bolts hold the brake on the posts against the full force of braking! It’s just one of those things that add some fun to this build…

Decaleurs are a great way to mount handlebar bags. They keep all hand positions accessible, and they make the bag easy to remove during stops.

In gravel races, I don’t usually remove my bag, so I’ve designed a simpler, stronger and lighter Gravel Decaleur. It weighs just 39 grams. It mounts to the stem and the bag, and it keeps the bag stable even on the roughest terrain. The flat piece is designed so it flexes in the center, reducing the load on the stem bolts and on the joint to tube that connects with the bag. No stress risers on this important piece!

Right now, there’s only a single prototype—which has already proven itself over thousands of miles, including this year’s Unbound XL. If there is demand, we’ll add it to our program. Tell us via our Suggestions Form if you’d like one.

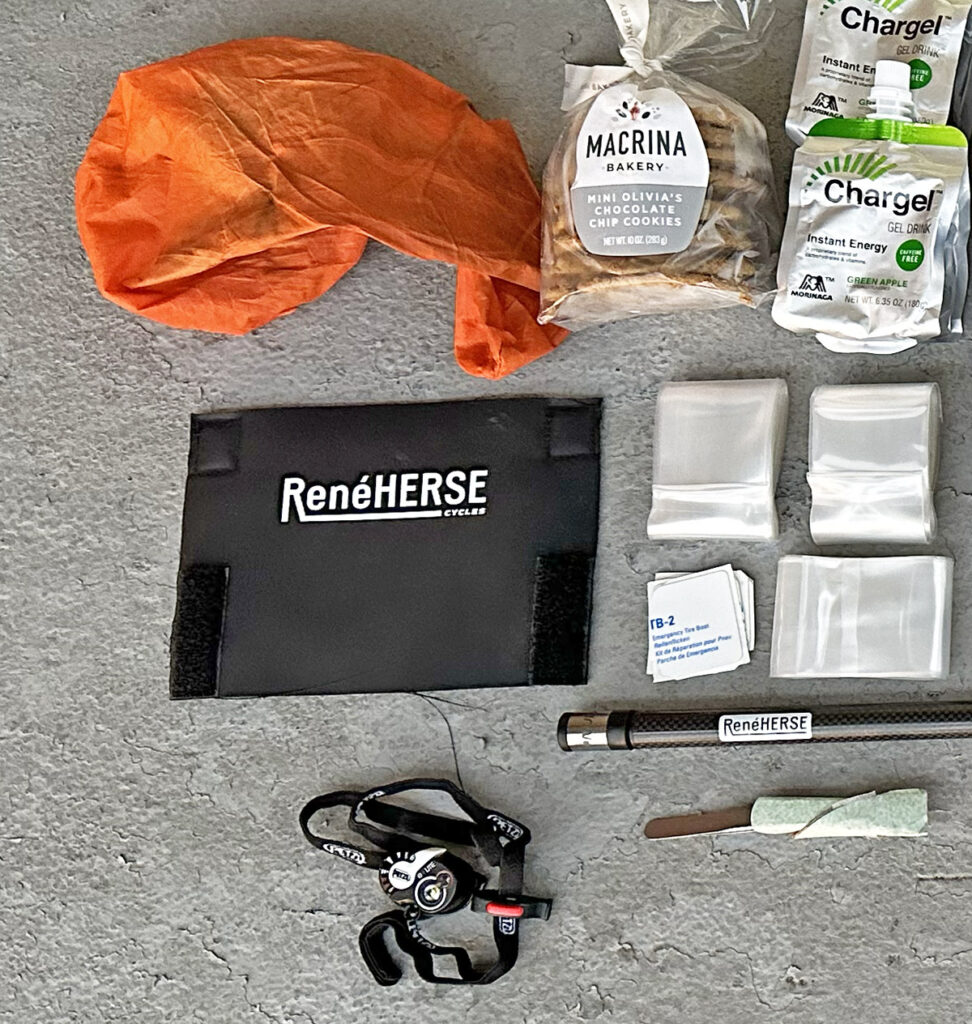

An article about lightweight bikes would not be complete without mentioning tools. It doesn’t make much sense to build an ultralight bike and then weigh it down with tools. Multi-tools weigh 100 grams or more. Even a single 4 mm Allen wrench weighs 13 g; a 5 mm is 24 g.

Key to reducing the tools I need was designing the bike from the outset so that it uses only a few standardized wrenches—no mixing Torx and Allen bolts! Even more important is designing every part so that nothing is likely to come loose.

The Rene Herse Rinko Headset Tool (above) weighs just 13 g, and it doubles as an 8 and 10 mm wrench. Hex bolts aren’t common these days, but they have a few advantages. One is that you can make ultralight wrenches to tighten them on the road.

On most rides, I carry the Rene Herse Rinko Headset Tool and a 5 mm Allen wrench. It’s not like my headset is likely to come loose, so I carry the tool mostly for the 8 and 10 mm sockets, which allow me to tighten and adjust most bolts on the bike. (Separate wrenches would weigh far more.) For example, I’ve used the tool to adjust the brake pads as they wear (above).

For Unbound XL this year, I didn’t carry any tools except two pumps (a frame pump for speedy inflation, a carbon NUDA minipump as a backup), three spare tubes, a tire boot, and a pair of tweezers to remove thorns from tires and scrape mud from wheels. If I had to portage over long distances, the lightweight frame pad would cushion my shoulder.

The only tool I actually used were the tweezers/mud scrapers, when we encountered a 2-mile-long mudbath of the stickiest peanut butter mud imaginable. (The photo shows the bike at the finish 100 miles later, after much scraping.)

That’s the story of all the parts on my Unbound XL bike. There are many great bikes out there—this one is different from most others lining up at ultra races, but it works well, and I enjoy riding it. I hope that some of the ideas behind is inspire some of your future builds.

More Information:

- Gravel Myths: 700C roll faster?

- A deep dive into this bike’s sister bike, the Rene Herse for the Oregon Outback

- Aerodynamics of gravel bikes

- Our book The All-Road Bike Revolution explores how bicycles really work